We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Sharpening and machining PCD tools optimally

Efficient, high-precision machining is the key to the production of PCD rotary tools.

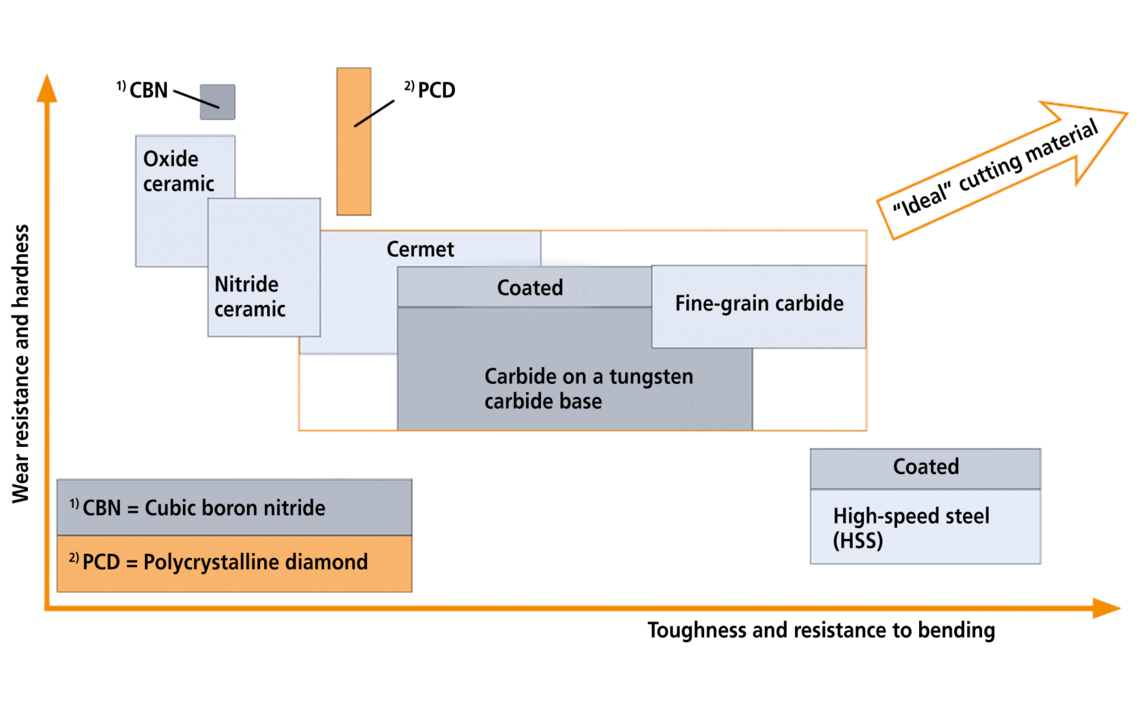

PCD (polycrystalline diamond) is a synthetically produced diamond cutting material, which can be used for machining wood, plastic and metal. The material is mainly characterised by a high degree of hardness and abrasion resistance.

This results in:

- Longer service life (fewer sharpening operations required)

- Higher cutting speeds (faster machining)

- Highly abrasive materials can be machined (greater range of applications)

- Consistent quality (better tolerances, high surface quality, less scrap)

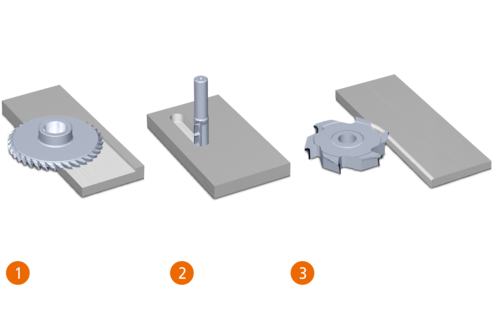

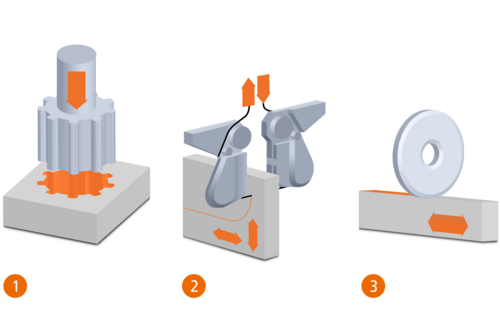

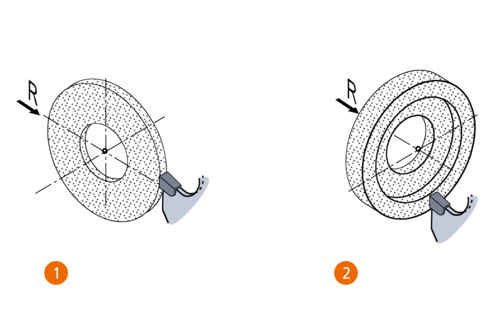

There are basically three types of eroding process: Sink erosion, wire erosion and disc/rotary erosion.

Wire erosion and disc/rotary erosion work according to the same erosion principle and achieve the best results in terms of precision and surface quality.

There are differences in the shape of the electrodes and their use. Therefore, some tooth and cutting edge shapes can only be machined by one of these two processes, e.g. no tooth flanks can be eroded with the wire erosion process, as this requires the finest contours and radii (both on the outside and inside).

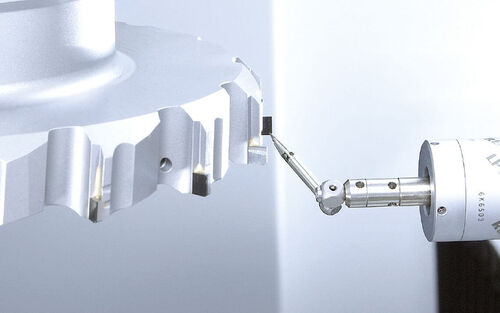

In order to determine the position and size of the PCD cutting edges, a fully automated measurement of the workpiece clamped in the machine is carried out before every erosion operation. To do this, one point per cutting edge is specified for the erosion machine. The machine then scans several points on the cutting edge automatically in accordance with the set value. Even complex profiles can be measured in this way.

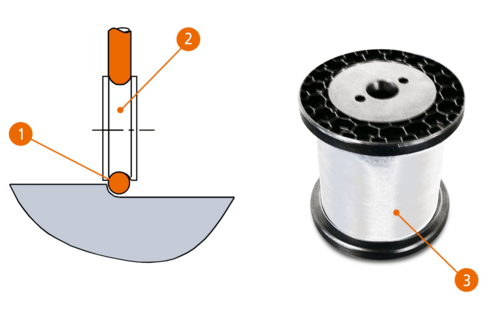

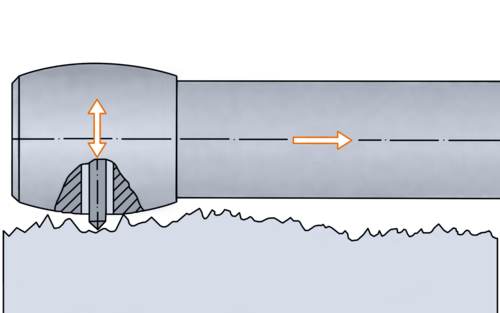

Eroding wire is used as an electrode during wire erosion. Copper and copper alloys are most suitable for this. Some of these wires are still coated with a layer of zinc, which results in better cutting power for certain materials.

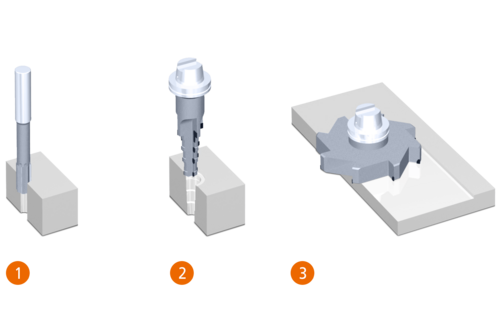

Electric discharge removal takes place between the continuously self-renewing wire electrode and the PCD cutting edge at the most minimum of clearance. The wire electrode is guided along the tool using two prisms according to the cutting edges. The small radius of the wire allows it to produce up to 0.1 mm radii on the tool.

This results in the finest of contours and profiles.

Discover the highest levels of precision and performance.

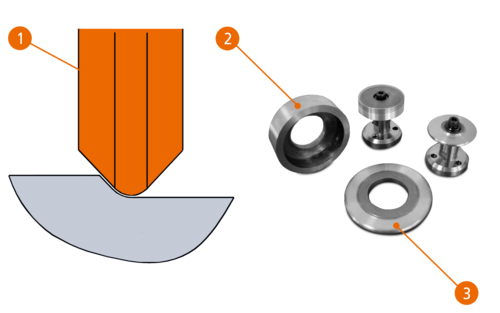

During disc/rotary erosion, removal takes place between the rotary electrodes and the PCD cutting edge at the most minimum of clearance.

Copper alloys are the most suitable for use in electrodes. However, the cutting material should be easy to machine in order to make dressing the disc electrodes easier.

In order to distribute the wear of the electrode over as large an area as possible and to keep its geometry constant for as long as possible, the disc performs a rotational motion during erosion. The rotary electrodes are clamped and dressed directly on the machine. This results in optimal concentricity as the dressed tool is attached directly to the machine stand. The advantage of disc erosion is that both the circumference and the end face of a rotary electrode can be used for erosion, and the flank surfaces can therefore also be machined.

Discover the possibilities:

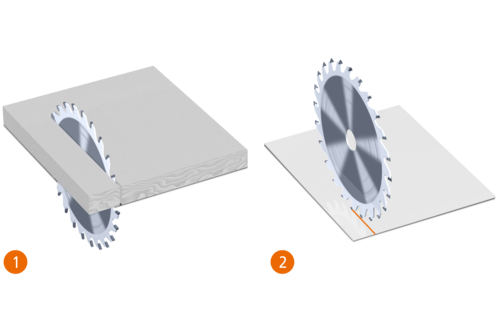

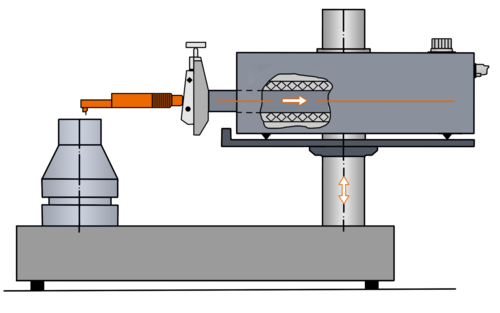

Disc erosion machines for complete machining of PCD-tipped tools.

Projection measurement:

The requirements regarding the precision of tools are extremely high. Some measuring machines therefore have an image of the tool projected onto a screen. The measurements are displayed across the traverse path of the tool with the help of a measuring computer.

Optical measurement:

In order to accurately determine the tool diameter, you need to measure with a camera or laser. The accuracy of this process is in the region of 1/1000 mm.

Surface measurement:

The surface can be measured with a skidded gauge or guided measuring system. For reference surface probe systems, both the roughness and the waviness of a surface are checked. To do this, a diamond with a tip of 2 µm probes across the surface, and while doing so, records the smallest surface irregularities on the workpiece. When measuring the surfaces on the PCD plates, reference is made to the surface value Ra in respect of the roughness value. The cutting edges of PCD-tipped tools are visually assessed: New technology makes it possible to assess the surface and cutting edge quality using high-resolution cameras.

Every day at VOLLMER, we are engaged in extremely intensive work with the profiles, cutting edges and complex geometries of modern PCD rotary tools. We therefore constantly research and try out new technologies and processes in order to optimise our machining and manufacturing processes further. We are happy to share our expertise in the form of targeted advice, and offer products which are precisely adjusted to particular requirements.

Your Contact

VOLLMER WERKE Maschinenfabrik GmbH88400 Biberach/Riß

Germany