We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Knowledge... simply explained Complex topics from the world of tools presented in an understandable way

From circular saws, carbide drills to PCD milling cutters - the world of grinding, eroding and laser machining is very complex. VOLLMER has been dealing with these topics for more than 111 years, and during this time we have done one thing above all: constantly learning and building up knowledge. We do not want to keep this know-how to ourselves. In our explanatory films we give you a comprehensible overview of the central aspects of our technologies and products.

Hybrid machining of PCD microtools

The word hybrid is derived from the Greek description for something that is bundled, crossed or mixed. In engineering, it describes a system which skilfully combines two technologies and therefore offers the best of both worlds. The combination of sub systems can give rise to brand-new positive features.

Production of carbide tipped circular saws

How is a carbide tipped circular saw produced? In our explainer video, we explain the individual manufacturing steps: laser cutting, surface grinding, heat treatment, tensioning & straightening, degreasing, brazing, sandblasting, grinding, polishing and final control. The film briefly and clearly explains what exactly is involved.

Properties of a grinding wheel

In this film we explain how a grinding wheel is constructed, what shapes and abrasives are available.

Correct repair of carbide tipped circular saw blades

When is the time to resharpen a carbide tipped circular saw blade? What is a wear bevel? What should be taken into account when resharpening? These and other questions are answered in our explanatory film on the repair of carbide tipped circular saws. Just have a look.

Eroding technologies

In VOLLMER machines, we distinguish between two types of eroding processes: wire erosion and disk/rotary erosion.

Wire erosion and disc/rotary erosion work according to the same erosion principle and achieve the best results in terms of precision and surface quality. There are differences in the shape of the electrodes and their use. For an overview, see our explanatory film.

Eroding

In this film we explain, among other things, what eroding is, how this process works and what conductivity means: Eroding refers to a thermally removal process in which electrically conductive materials, such as polycrystalline diamond (PCD), can be machined. Material is removed from the workpiece by sparking between the workpiece and an electrode. The material is melted out and vaporized. This process is non-contact and can produce extremely sharp edges.

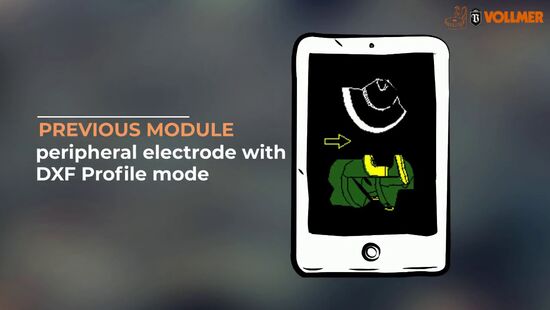

Optimized HP 360 software

Technological advancement never rests - this is especially true in the area of software. VOLLMER specialists are constantly developing applications and adapting them to your tasks and requirements. Our software updates ensure that your VOLLMER machine is always up to date. The performance range of your machine is thus permanently expanded, flexibility is sustainably increased and your production process is maintained at the highest level. Find out more about the possibilities and advantages of the extended software program HP 360!

The carbide tipped circular saw

The carbide tipped circular saw is a rotating and chip-removing cutting tool. It carries the carbide teeth, which cut material.

Tooth shapes of carbide tipped circular saws

In this video we would like to take a closer look at the different tooth shapes of a carbide-tipped circular saw.

JSON-Converter

In this video, we explain step by step how you can optimise your processes with the JSON-Converter.

With the help of our JSON-Converter, processing programmes can be created fully automatically.

- Less active operator effort

- Cost and time savings

- Increased process stability

- No programming errors

Laser Technology // Part 1

With the laser technology, we are expanding our product portfolio alongside our tried-and-tested grinding machines and innovative eroding machines to become a fullliner. In our latest video, we’ll walk you through the fundamentals of laser processing. Discover how laser beams differ from regular light and explore their applications in tool processing. Interested in learning more?

Don’t hesitate to reach out to us!

Your Contact

VOLLMER WERKE Maschinenfabrik GmbH88400 Biberach/Riß

Germany