We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

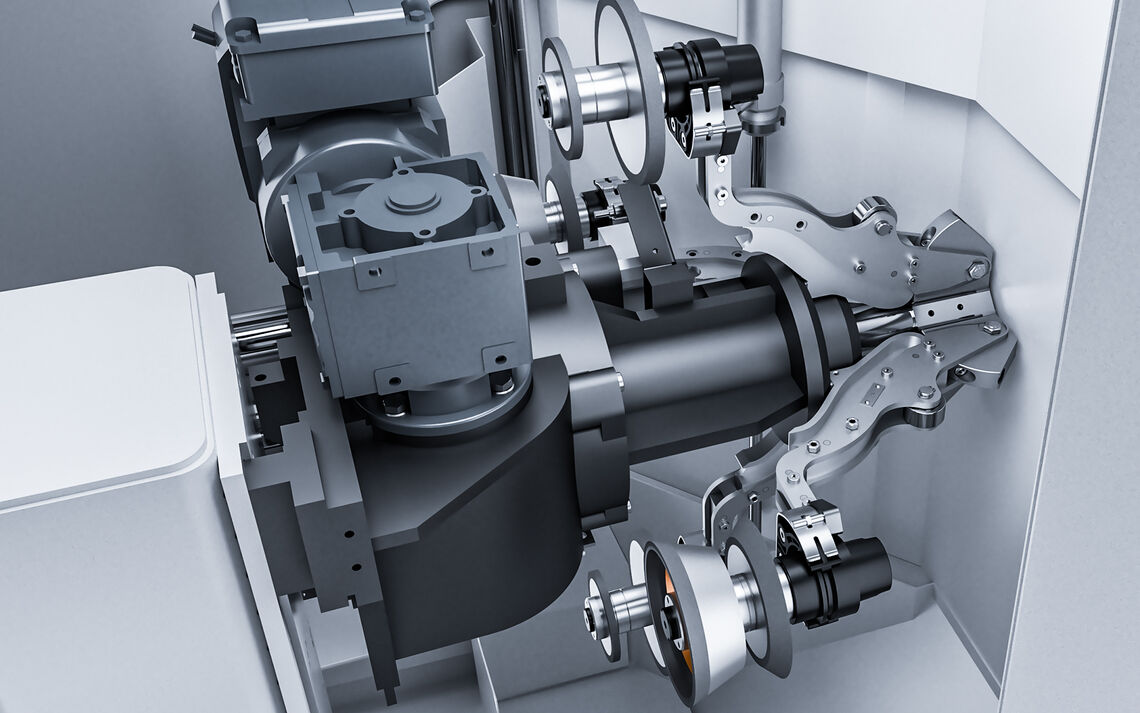

STABLE WALL CONCEPT

The extremely rigid and compact construction is the result of temperature-stable polymer concrete foundation. This offers the operator optimal accessibility and work area visibility with unparalleled process stability.

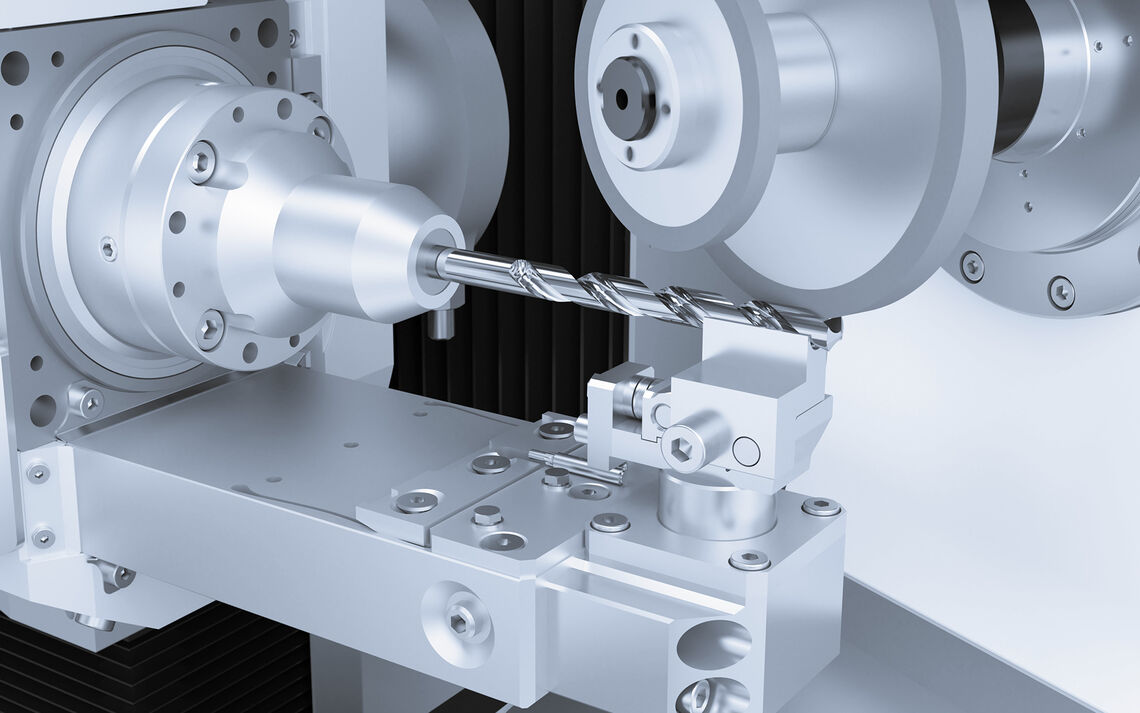

MULTI-LEVEL MACHINING

With the ground-breaking double vertical grinding spindles where the grinding wheels are located at the C axis pivot point, the kinematics reduce machining times with shorter linear-axis travel distances.

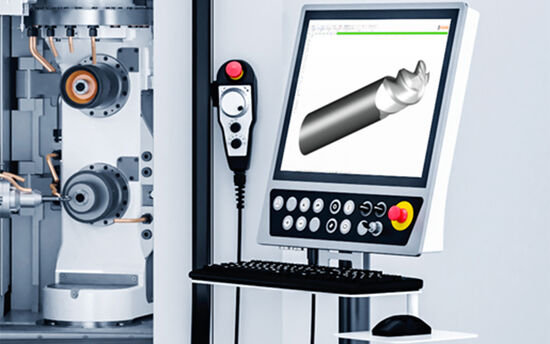

MODERN OPERATING CONCEPT

The height-adjustable control panel with a 19" touchscreen facility is ergonomically positioned to provide the optimum viewing position of the machining area.

INTUITIVE NUMROTO CONTROL SYSTEM

The tried-and-tested software provides a complete 3D tool and machine simulation, combined with unsurpassed collision monitoring for complete process control.

INCLUDING IOT GATEWAY

The keyword is Industry 4.0: Our machines are enabled with an IoT gateway that is fitted as standard. This opens the door to the digital world for your business.

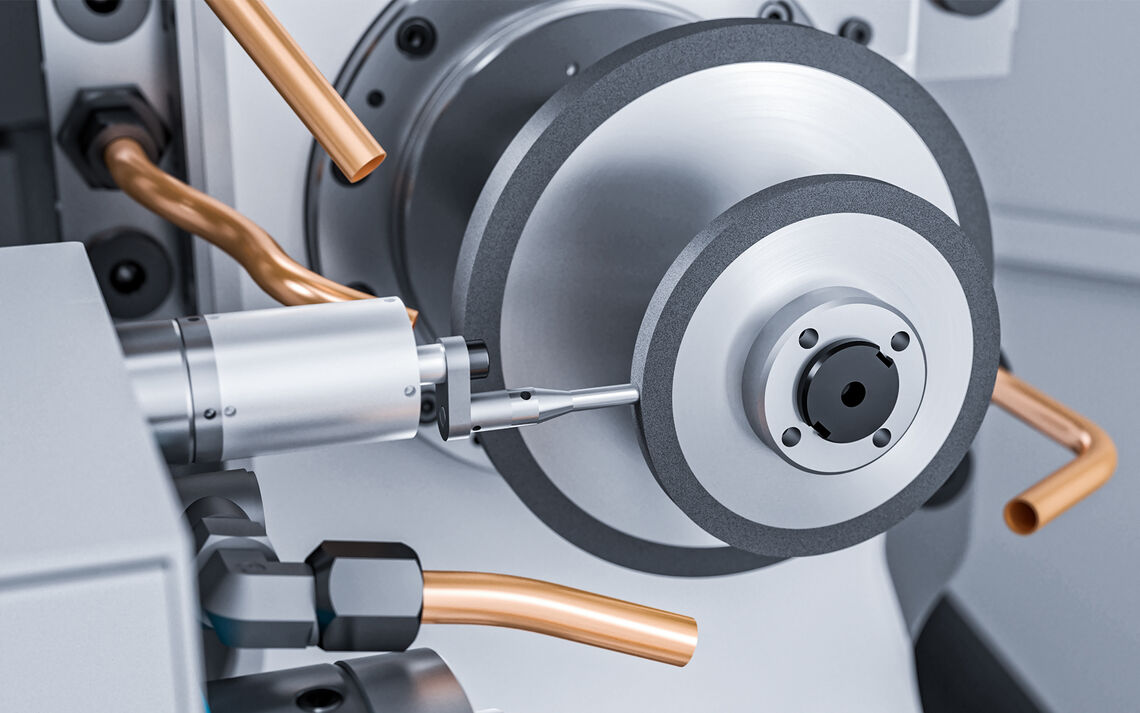

COOLING CONCEPT

The plate heat exchanger guarantees effective and sustainable cooling of the torque motors and the grinding spindles. And the best part? No additional chiller unit is required.

IT IS THE PERFECT TIME FOR A VOLLMER. BUT WE ARE OFFERING YOU TWO.

For everybody that has been waiting, the time has finally come. You can now get your hands on a real VOLLMER, and the best part: We are not just introducing one special edition but two.

The VGrind neon and the VGrind argon both have everything that makes a grinding machine a VOLLMER: The tried-and-tested multi-level machining with the double spindle, temperature-stable polymer concrete, torque motors on the rotational axes and the intuitive NUMROTO control system on a modern, ergonomic control panel. Simple, reliable, precise.

We have developed these two models especially for tool grinders that want to act and react quickly when customer enquiries and orders are received. If you have always wanted to own a VOLLMER, the opportunity to do so has never been better. Precise, productive and affordable.

SOFTWARE NUMROTOPLUS®

VOLLMER consciously opted for a well known system that is already established on the market. The logically structured interface guarantees intuitive handling. With established programming systems, a huge variety of tools can be manufactured and resharpened. You can change any detail of your tools and adapt them to your individual requirements. Fully informed: Thanks to a perfect 3D simulation of the tool and machine. And with collision monitoring, you can always stay on the safe side.

PERFECTLY EQUIPPED FOR YOUR REQUIREMENTS.

With a wheel measurement probe, glass scales and an intelligent cooling concept with a plate heat exchanger – the VGrind neon makes precision easy. Whether you producing a tool or carrying out resharpening service whenever it is required. The VGrind neon ensures you hit the ground running with productive, precision, high-quality results.

STABLE WALL CONCEPT

The extremely rigid and compact construction is the result of temperature-stable polymer concrete foundation. This offers the operator optimal accessibility and work area visibility with unparalleled process stability.

MULTI-LEVEL MACHINING

With the ground-breaking double vertical grinding spindles where the grinding wheels are located at the C axis pivot point, the kinematics of the VGrind neon reduce machining times with shorter linear-axis travel distances.

MODERN OPERATING CONCEPT

The height-adjustable control panel with a 19" touchscreen facility is ergonomically positioned to provide the optimum viewing position of the machining area.

INTUITIVE NUMROTO CONTROL SYSTEM

The tried-and-tested software provides a complete 3D tool and machine simulation, combined with unsurpassed collision monitoring for complete process control.

INCLUDING IOT GATEWAY

The keyword is Industry 4.0: Our machines are enabled with an IoT gateway that is fitted as standard. This opens the door to the digital world for your business.

WHEEL MEASUREMENT PROBE

Grinding wheel alignment and machine is now fully controlled with the wheel measurement probe.

OPTIONAL STEADY REST

For optimal grinding results, especially with longer tools – the steady rest provides stability and enhanced results with a flexibly adjustable automatic stroke.

COOLING CONCEPT

The plate heat exchanger guarantees effective and sustainable cooling of the torque motors and the grinding spindles. And the best part? No additional chiller unit is required.

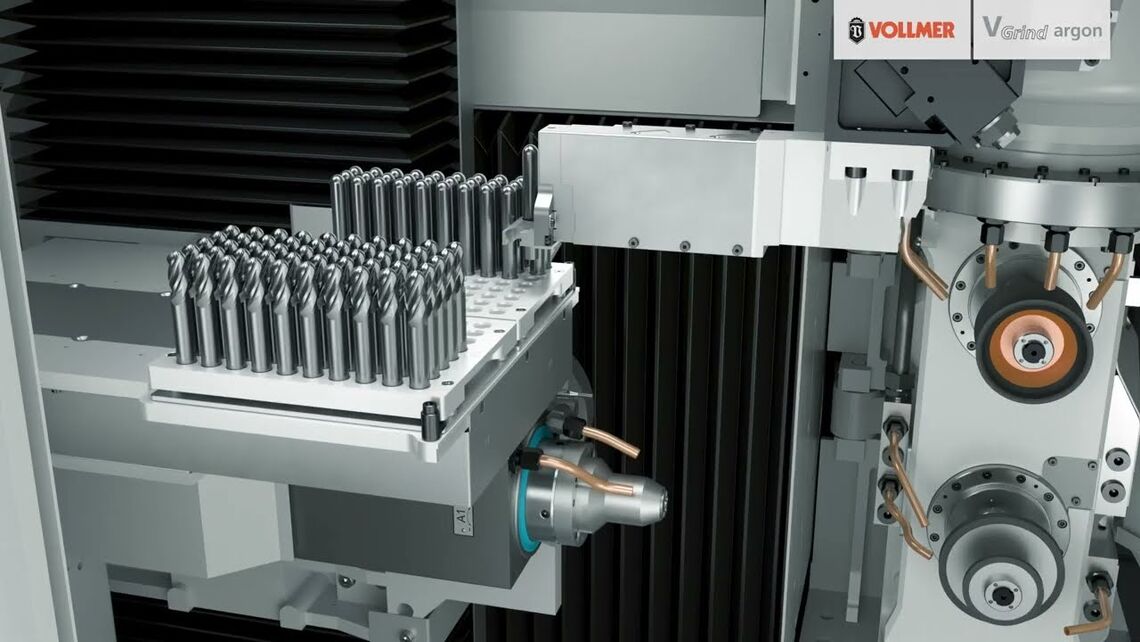

WITH ENHANCED COMFORT.

Same enclosure and same equipment – not quite! Everything the VGrind neon can do, the VGrind argon can do too – and a bit more. With a four-station grinding-wheel changer and an internal pallet loader, the VGrind argon offers increased comfort and flexibility for different batch sizes. With your VGrind argon, you will automatically experience greater enjoyment. And greater flexibility, ease of use and greater output.

STABLE WALL CONCEPT

The extremely rigid and compact construction is the result of temperature-stable polymer concrete foundation. This offers the operator optimal accessibility and work area visibility with unparalleled process stability.

MULTI-LEVEL MACHINING

With the ground-breaking double vertical grinding spindles where the grinding wheels are located at the C axis pivot point, the kinematics of the VGrind neon reduce machining times with shorter linear-axis travel distances.

MODERN OPERATING CONCEPT

The height-adjustable control panel with a 19" touchscreen facility is ergonomically positioned to provide the optimum viewing position of the machining area.

INTUITIVE NUMROTO CONTROL SYSTEM

The tried-and-tested software provides a complete 3D tool and machine simulation, combined with unsurpassed collision monitoring for complete process control.

INCLUDING IOT GATEWAY

The keyword is Industry 4.0: Our machines are enabled with an IoT gateway that is fitted as standard. This opens the door to the digital world for your business.

WHEEL MEASUREMENT PROBE

Grinding wheel alignment and machine is now fully controlled with the wheel measurement probe.

OPTIONAL STEADY REST

For optimal grinding results, especially with longer tools – the steady rest provides stability and enhanced results with a flexibly adjustable automatic stroke.

COOLING CONCEPT

The plate heat exchanger guarantees effective and sustainable cooling of the torque motors and the grinding spindles. And the best part? No additional chiller unit is required.

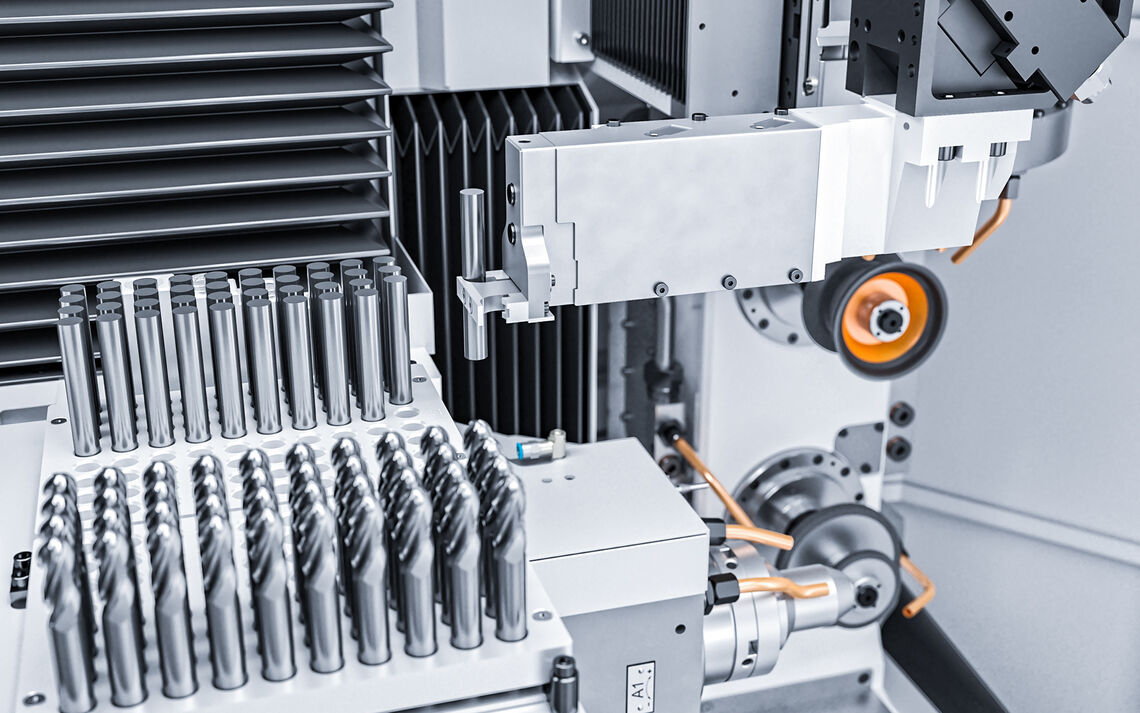

WITH ENHANCED COMFORT THANKS TO:

- NTERNAL TOOL AUTOMATION

With an integrated pallet loader, the VGrind argon increasescapacity, flexibility and automation – all in a compact floor area.

- FOUR-STATION GRINDING-WHEEL CHANGER

With four grinding wheel packages in the automatic wheel changer, the VGrind argon delivers even greater flexibility for your grinding processes.

Your Contact

Ehinger Straße 34

88400 Biberach/Riß

Germany

Phone: +49 7351 5710

Fax: +49 7351 571130

info@vollmer-group.com