We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

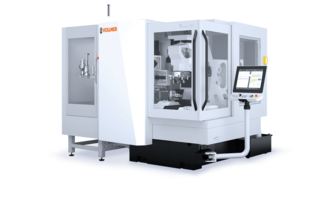

Click by click to the right machine The VOLLMER product finder

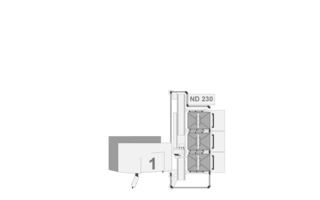

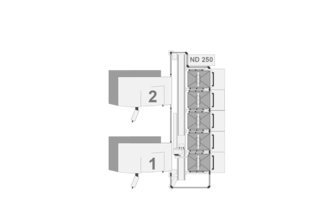

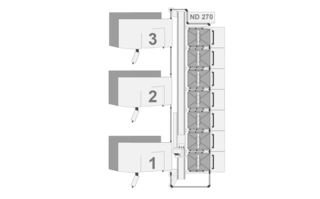

With our product finder, you'll find the perfect VOLLMER solution for your individual requirements quickly and easily. The more information you enter, the more accurate our machine recommendation will be. It usually only takes three clicks – tool type, grinding material, and machining process – to find the right product. You can then refine your search further. And, of course, our experts are happy to advise you in person.