We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

POWERFUL EROSION MACHINES FOR PCD TOOL MACHINING

Efficient, high-precision machining is the key to the manufacture of PCD rotary tools.

VOLLMER has a unique portfolio of intelligent, powerful high-tech CNC-controlled erosion machines specifically for machining complex rotary tools – both for production and service.

BENEFITS OF VOLLMER EROSION MACHINES FOR PCD

With VOLLMER, you have a strong and forward-thinking partner by your side. We will help you establish an effective presence when facing the global competition.

As a result, you will benefit from:

- High reliability

- Precise results

- Greater operating comfort

- Maximum productivity in manufacture of rotary tools

- Tailored Services

For machining PCD tools, Vollmer's portfolio includes wire and disc erosion machines, which are lightweight and easy to operate. With the unique operating concept, you can carry out complex sharpening or grinding tasks quickly, safely and reliably after just a short period of training. Moreover, thanks to the high accuracy and surface quality achieved by every VOLLMER machine, grinding can even be omitted in many cases.

Whether the automotive, aviation or aerospace industry, whether machining aluminum, magnesium, MMX or highly abrasive laminates: VOLLMER offers the technologies you need for manufacturing and processing the respective rotary tools. Of Course, the same applies for complete machining including measuring, eroding, grinding and polishing. Special machine configurations with integrated infeed device and workpiece magazines enable fully automated sharpening around the clock, on a multi-shift basis and on weekends. With "ExLevel", we provide you with an intelligent software solution, which creates the most realistic simulation of your tool production.

IDEAL SOLUTIONS FOR THE FOLLOWING APPLICATIONS

- Wood-cutting PCD-tipped precision tools

- Metal-cutting PCD-tipped precision tools

- PCD-tipped circular saw blades

- Automation of machines for machining around the clock

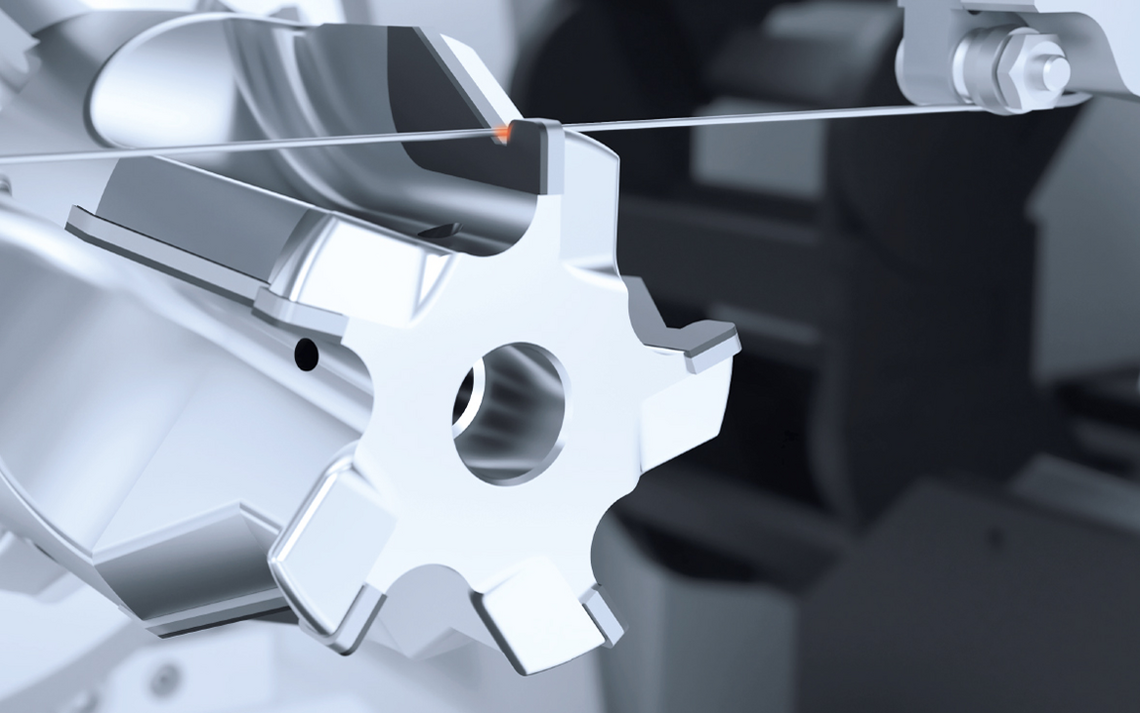

Wire erosion

During wire erosion, machining takes place in a non-conductive medium. The wire serves as an electrode and is guided so close to the workpiece that a spark is produced, which melts and vaporizes the material. VOLLMER wire erosion machines are ideally suited for machining tool cutting edges made of PCD, PCBN and other ultra-hard cutting materials, and impress with maximum precision and performance. The right decision for rotary tools with complex profiles and geometries.

Disc erosion

During disc erosion, a copper-tungsten disc functions as a rotating electrode. VOLLMER disc erosion machines guarantee maximum accuracy and reliability during the eroding process, whether for manufacturing or resharpening wood- and metal-cutting PCD tools. Innovative technologies facilitate measuring, eroding, grinding and polishing – all in just one clamping operation.

For more information, please can contact us any time. Or come visit us in our Technology and Training Center (TDZ) in Biberach and see the erosion machines for yourself.

Your Contact

115 Enterprise Drive

Pittsburgh, PA 15275

USA

Phone: +1 412 2780655

Fax: +1 412 2780520

info-us@vollmer-group.com