We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

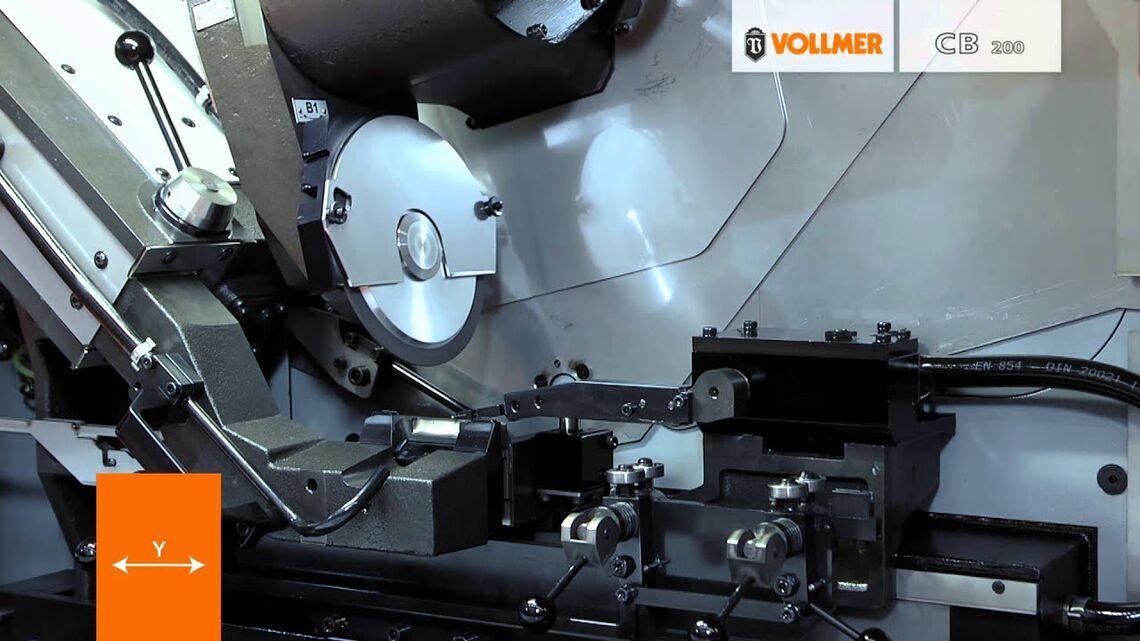

THE MACHINE CONCEPT

The CB 200 effortlessly meets all requirements for the manufacture of carbide-tipped band saws. In impressive quality, with a long service life and at an attractive purchase price.

- Four CNC-controlled axes plus VOLLMER components guarantee ideal freedom of coordination and enable fast and accurate completion of challenging sharpening tasks

- Proven VOLLMER drive technology for dynamic and reliable machining

- Setup is performed manually

- Sophisticated VOLLMER modules with control and CNC technology for maximum process reliability

- High flexibility owing to the possibility of being combined with VOLLMER CAF 310, CB 400 and CBF 40

THE APPLICATION

VOLLMER developers have done the groundwork so that you can use the CB 200 to its full potential:

- All commonly used tooth geometries for metalworking including a multi-surface program are saved as standard – all the way through to group toothing

- Grinding speed can be controlled separately per surface

- Individual selection of bevel grinding angle and tooth heights

- Flexible selection of feed mode types: Lifting feed pawl or sliding pawl for variable toothing

YOUR MAIN ADVANTAGES AT A GLANCE:

- MORE PRODUCTIVITY: Maximum grinding performance and optimized sharpening results. Exemplary ease of use.

- MORE EFFICIENCY: High performance under extremely economical conditions.

- MORE FLEXIBILITY: Four CNC axes. Machines all commonly used tooth geometries in one cycle – including group toothing

CB 200: Technical Data

| CB200 | |

|---|---|

| WERKSTÜCKDATEN | |

| BANDSÄGEBLÄTTER | |

| Bandsägeblätter mit Blattbreite | 9 - 210 mm |

| Bandsägeblätter mit Blattlänge | ≥ 6 m |

| Bandsägeblätter mit Stammblattdicke | ≥ 3 mm |

| ZAHNGEOMETRIE | |

| Spanwinkel | -20° - +35° |

| Freiwinkel | 0° - +20° |

| Schrägungswinkel | ≤ 45° |

| Zahnteilung | 4,2 - 100 mm |

| WERKZEUGDATEN | |

| GESCHWINDIGKEITEN | |

| Schleifgeschwindigkeit | 0.1 - 20 mm/s |

| SCHNITTSTELLEN | |

| Anschlusswert elektrisch | 5,7 kVA |

| KÜHLMITTELEINRICHTUNG | |

| Förderleistung (Pumpe) Kühlmittel Emulsion | 50 l/min |

| KÜHLMITTELEINRICHTUNG INTERN | |

| Kühlmittelbehälter | 140 l |

Your Contact

Country

VOLLMER OF AMERICA CORP.

Further contacts

115 Enterprise Drive

Pittsburgh, PA 15275

USA

Phone: +1 412 2780655

Fax: +1 412 2780520

info-us@vollmer-group.com