We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Loroch TWIN machines are a must for Slovenian tool manufacturer Cajhen 2024-01-23

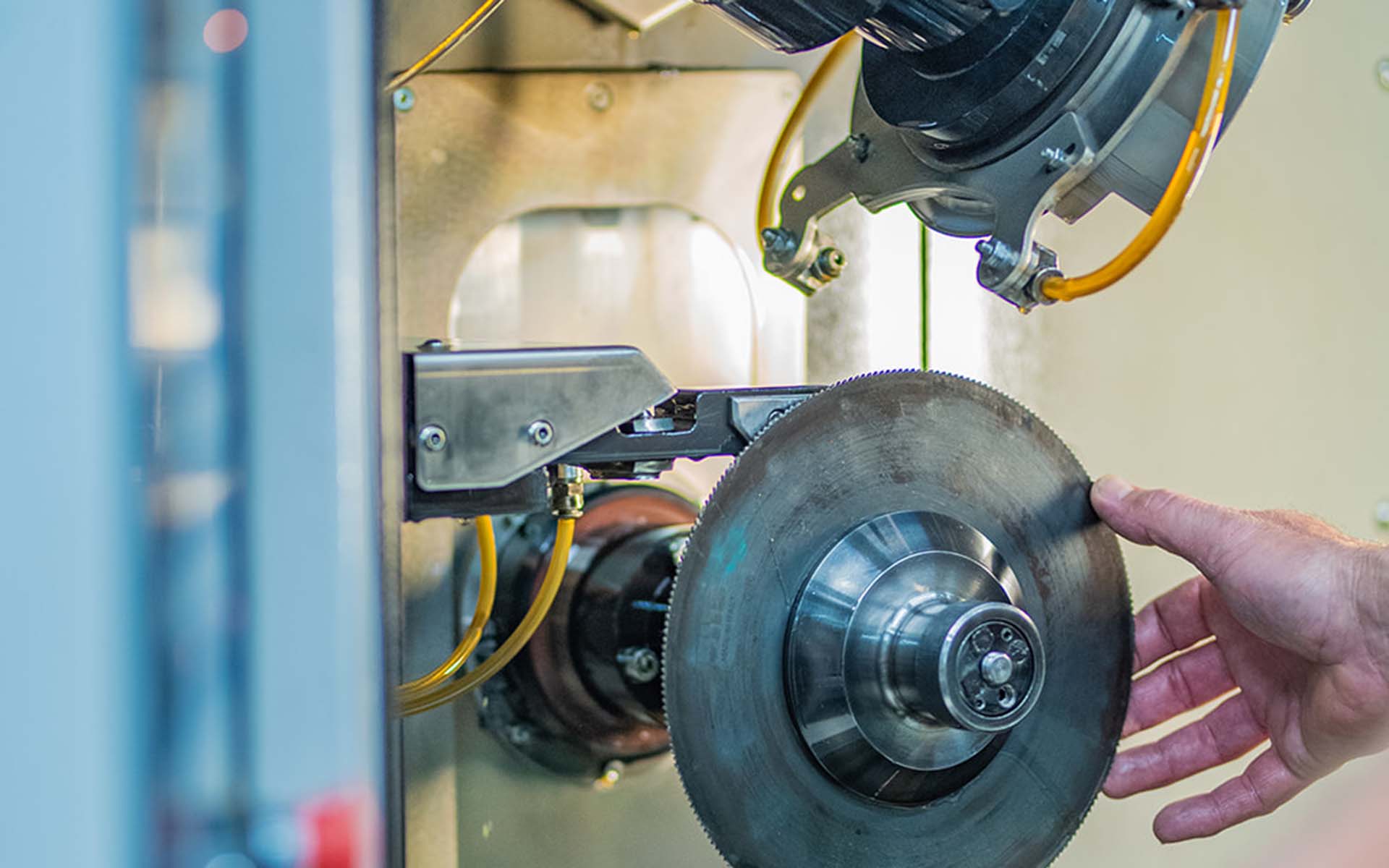

to overviewTool manufacturer Cajhen is Slovenia's leading manufacturer of rotary tools and circular saws. In addition to serving the local market, the company is also firmly established in south-east Europe and is increasingly supplying its products to the EU, Asia and Latin America. Part of the VOLLMER Group, Hessian sharpening specialist Loroch has supplied Cajhen with several grinding machines, which the tool manufacturer uses to produce and resharpen its circular saws. Loroch recently supplied Cajhen with two new TWIN 860 grinding machines, which can "twin" both high-speed steel and carbide-tipped circular saws.

The Slovenian town of Laško has around 13,000 inhabitants and is located in the Štajerska region, the historical area of Lower Styria. The town is not only known for its tasty beer and relaxing thermal baths, but also for the tool manufacturer Cajhen. The family-run company was founded in 1969 as a small turning shop and began producing cutting tools made of carbide and ultra-hard cutting materials such as PCD, MCD or CBN in 2001. Today, Cajhen is a leading tool supplier not only in Slovenia, but also in south-east Europe, with around two thirds of its products being sold on the domestic market. Cajhen's customer base spans the automotive and aerospace industries as well as foundries and other sectors with high-volume series production. Cajhen also manufactures cutting tools and circular saws on behalf of other tool manufacturers.

Loroch machines enable Cajhen to automate production

"More than 90% of our production is made up of special tools that we adapt to the individual requirements of our customers," says Matjaž Cajhen, CEO of Cajhen d.o.o.; "For this reason, it is crucial that we can use high-precision CNC machines, like our Loroch machines, that guarantee automated tool processing around the clock."

With its 30 employees and more than 25 CNC machines, Cajhen produces around 50,000 customised cutting tools and circular saws every year: It takes 24 hours from the enquiry about a special tool to the quotation, and the average delivery time is three weeks. The company also resharpens more than 70,000 tools and saws every year. Based in Mörlenbach in southern Hesse, Loroch is part of the Biberach-based VOLLMER Group and the company has been supplying Cajhen with grinding equipment to machine its high-speed steel circular saws for many years. Cajhen's production hall in Laško includes the Loroch Evolution K850-M and Solution K850 models which serve as compact service centres for sharpening and chamfering circular saw blades.

The Loroch TWIN 860 sharpens high-speed steel and carbide-tipped circular saws

"In the circular saw sector, we want to expand our range both with our brand and our renowned partners such as the Italian company Julia," explains Matjaž Cajhen. "For this reason, we recently opted for two new Loroch TWIN 860 machines, which will also help us to make progress in the carbide-tipped circular saw sector."

The Loroch "twin" is so named because the CNC-controlled machine can automatically sharpen high-speed steel (HSS) and carbide-tipped (HW) circular saws using two different processes. With carbide-tipped circular saws with thick cutting widths in particular, the feed on the TWIN 860 is not carried out via a feed pawl as usual, but via the precisely controlled centre drive device. The carbide-tipped saw tooth is then clamped and machined solely using the twin-axis controlled grinding head. Thanks to the combined TWIN process, Cajhen not only saves space for a second machine, but can also control the machining of its high-speed steel and carbide-tipped circular saws uniformly and intuitively via a touchscreen.

Cajhen sets its sights on global growth thanks to Loroch technology

By investing in the two new Loroch machines, Cajhen aims to sustainably increase its growth and expand its global business in particular. In addition to the European market, the focus is particularly on Latin America and Asia, where it has already established good partnerships. Thanks to state-of-the-art machines such as those from Loroch, Cajhen's engineers can develop innovative tools and circular saws that offer long service lives and enable high-precision machining of metal, wood or composite materials. The tool manufacturer also offers full control of its cutting tools, which are provided with corresponding measurement records.

"As part of the VOLLMER Group, Loroch has a global presence, which means that we not only operate worldwide as a supplier of grinding machines, but can also support our customers as a comprehensive service provider when it comes to sharpening," states Hartmut Kälberer, CEO of Loroch GmbH. “Our new TWIN 860 grinding machine in particular shows how we can profitably bridge the gap between the machining of high-speed steel and carbide-tipped circular saws and thus innovatively expand the portfolio of the entire VOLLMER Group.”

Your Contact

VOLLMER WERKE Maschinenfabrik GmbH88400 Biberach/Riß

Germany