We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Siberian toolmaker relies on Swabian sharpening technology 2018-09-19

to overviewIn the city of Tomsk in West Siberia, the toolmaking company Tomsky Instrument is relying on the sharpening technology from VOLLMER, the specialists for grinding and eroding machines based in the Swabian town of Biberach. Tomsky Instrument is using two <link https: www.vollmer-group.com en-uk products solutions-for-rotary-tools grinding-carbide vgrind-360 iconlink--external>VGrind 360 tool grinding machines to manufacture carbide rotary tools. The milling cutters, drills and reamers produced by the Russian manufacturer are used around the world in car, train and aeroplane manufacturing. Primarily, however, the company supplies the domestic metal industry and the West Siberian oil and gas sector, as well as West Siberia's large wood industry.

With over 300 employees, Tomsky Instrument specialises in the manufacture of carbide tools such as milling cutters, drills, reamers, countersinks and taps. The company is one of Russia's leading manufacturers of rotary tools for metalworking and woodworking: Every second company in Russia that uses rotary tools is on Tomsky Instrument's customer list. The company also exports its tools to all continents.

Carbide tools for metal and wood

"Whether it is for the manufacture of aeroplanes, trains or cars, our milling cutters and drills are in action worldwide wherever companies are cutting metals and plastics," says Sergey Shvartsev, Director of Tomsky Instrument. "But our tools are also used in the petrochemical and woodworking industries – industries that are strongly represented here in Western Siberia."

The region east of the Ural Mountains has huge deposits of oil and natural gas and possesses vast woodlands in the Siberian taiga. For example, Lesosibirsk, the Russian capital of the timber industry, is only roughly 500 kilometres away from Tomsk, as the crow flies – a stone's throw in terms of Siberian dimensions. And whoever strolls through Tomsk and marvels at the famous timber houses with their delicate carvings can assume that they were produced with milling cutters and form cutters from Tomsky Instrument.

Grinding machines in use around the clock

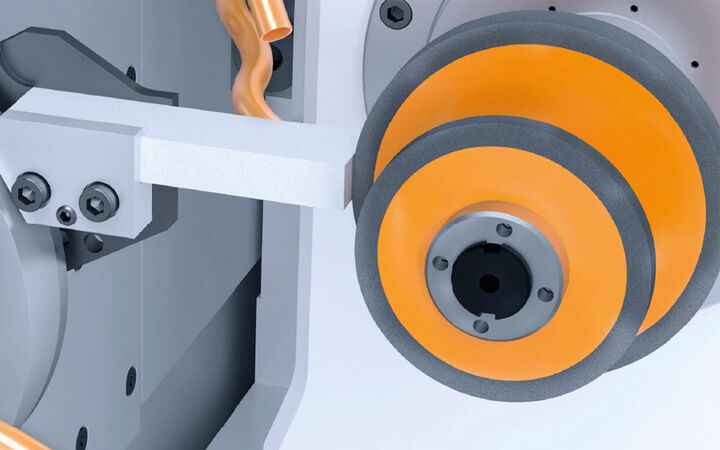

In order to meet the growing demand for carbide tools, Tomsky Instrument has opted for two VOLLMER <link https: www.vollmer-group.com en-uk products solutions-for-rotary-tools grinding-carbide vgrind-360 iconlink--external>VGrind 360 tool grinding machines and the <link https: www.vollmer-group.com en-uk products solutions-for-rotary-tools grinding-carbide vgrind-360 iconlink--external>HP 160 automation solution. The <link https: www.vollmer-group.com en-uk products solutions-for-rotary-tools grinding-carbide vgrind-360 iconlink--external>VGrind 360, with its two vertically positioned spindles, boasts modern kinematics which enable multi-level machining. The workpieces can be ground at the optimal pivot point of the C axis on both grinding spindles. This spindle positioning solves the common problems related to fixed and floating bearings, which leads to more precise results when machining workpieces. The <link https: www.vollmer-group.com en-uk products solutions-for-rotary-tools grinding-carbide vgrind-360 iconlink--external>HP 160 pallet magazine enables Tomsky Instrument to carry out automatic machining around the clock. The magazine can hold up to 272 workpieces and automatically feed them to the grinding machine.

Growing together for the future

The fact that Tomsk has developed from the end of the 19th century to become the science and cultural capital of Siberia makes the city a suitable location for the toolmaker. This means that more than 20 percent of the 500,000 inhabitants are students who are registered at the Tomsk State University, Tomsk Polytechnic University or one of the dozens of other educational institutions. Since many of the courses on offer are related to engineering, Tomsky Instrument can choose from a large selection of young engineers for its in-house research and development work. In addition, the toolmaker also works closely with local research institutes in order to jointly develop innovative production processes and to test new high-alloyed steels for toolmaking.

"Russia is an important market for us, which is why we established our own VOLLMER subsidiary in Moscow two years ago," says Dr Stefan Brand, CEO of the VOLLMER Group. "Although the Eastern European market developed out of a tradition of woodworking, it is tending increasingly towards the metalworking industry. This in turn raises demand for our grinding and eroding machines, as these are required for precise and efficient machining of carbide and diamond tools."

Your Contact

VOLLMER UK LTD.Town Street, Sandiacre

Nottingham NG10 5BP