We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Efficient sharpening for tool manufacturing

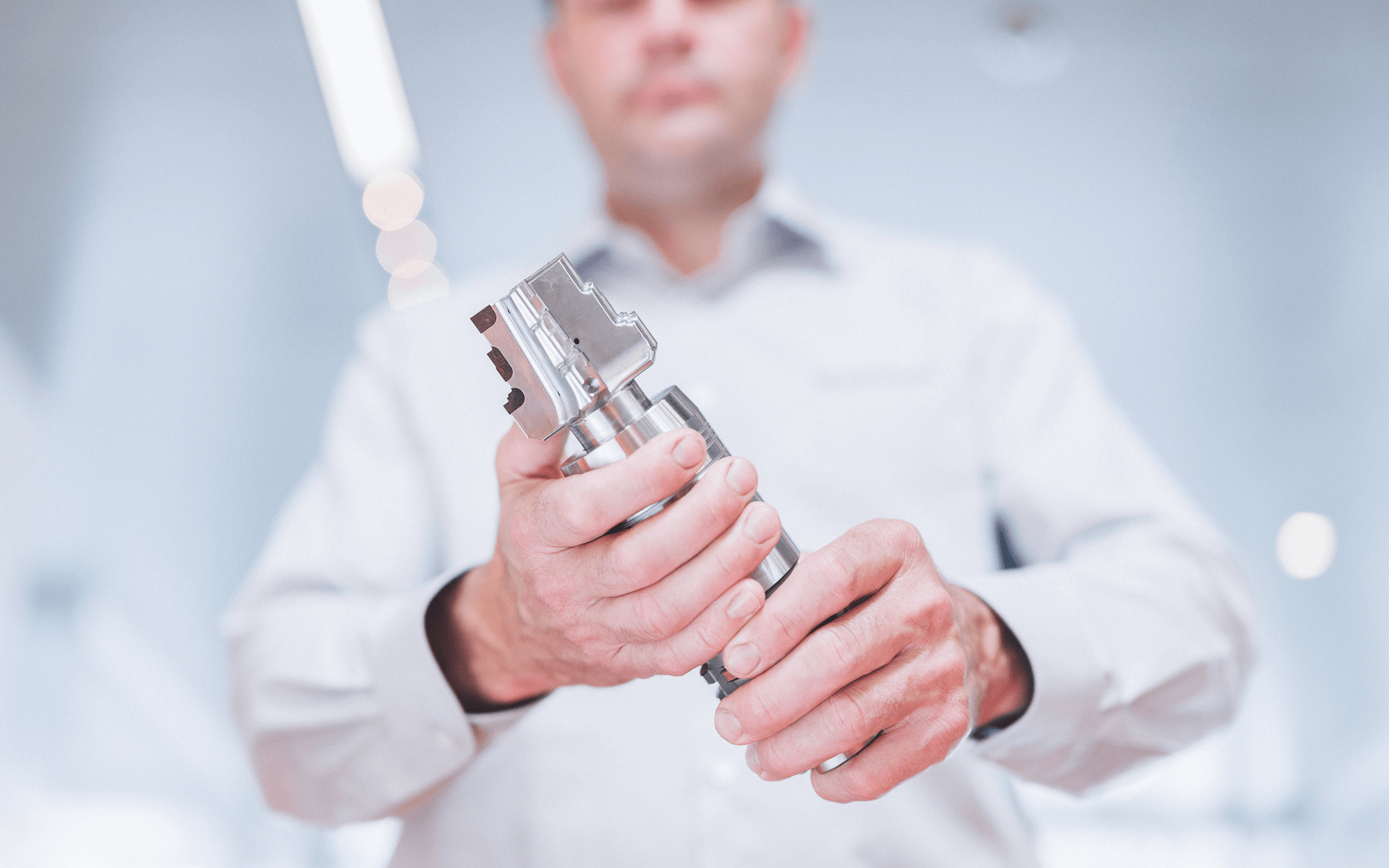

Whether the automotive, aviation or aerospace industry, furniture manufacture or the production of cell phones: It's all down to the right tools. Machining materials such as aluminium, magnesium or MMX often requires complex tool geometries with the maximum surface quality. A sophisticated, reliable and highly-efficient sharpening and grinding process is therefore the basic prerequisite for all successful tool manufacturing.

VOLLMER offers a varied portfolio of innovative technologies and machines for the production and processing of machining tools such as drills or milling cutters, whether through erosion of PCD or grinding of carbide. Disc erosion, wire erosion or complete machining including measuring, eroding, grinding and polishing: VOLLMER has the ideal solution. And with "VPulse EDM" it has a progressive erosion technology to allow for particularly finely-dosed or particularly productive machining. In the carbide grinding sector, the VGrind range has set precision and productivity standards for years.

Process reliability – right from the start

Just as crucial as the performance of the machines used is optimum integration into your company processes – and their continued further development. Intelligent automation solutions with workpiece magazines and infeed devices result in high productivity. And the intensive consultation and training by the VOLLMER experts guarantee the perfect integration in your production process right from the start. Comprehensive services from projection to maintenance and software and right through to original spare parts with legendary VOLLMER quality are protecting profitability for the future. You can count on VOLLMER.

Our solutions

With VOLLMER as your partner, you are not only sharpening your band saws, circular saws or rotary tools but also your profile in the face of the competition.

Your Contact

VOLLMER UK LTD.Town Street, Sandiacre

Nottingham NG10 5BP