We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

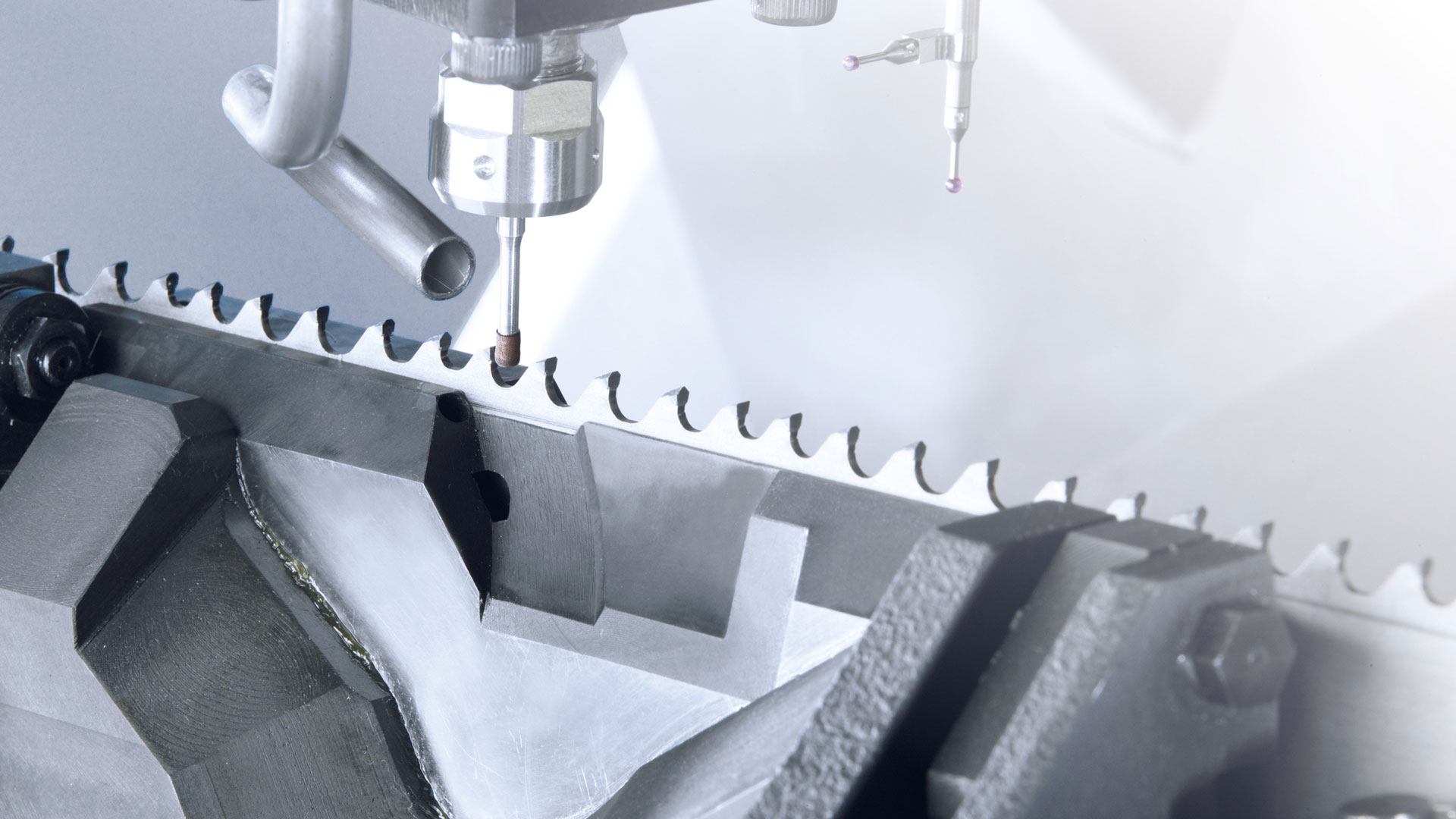

VOLLMER GRINDING MACHINES FOR METAL PROCESSING BANDSAWS THE WAY TO MAKE YOUR MACHINES RUN SMOOTHLY

Carbide-tipped band saw blades are finding more and more applications in the metal-cutting industry. They are mainly distinguished by their small dimensions in relation to the often oversized pieces that need to be cut down. The advantage of carbide-tipped bandsaw blades for cutting metal lies in the very narrow cutting channel and the small machining losses.

In carbide-tipped bandsaws, small carbide pieces are welded onto a special carrier material that is highly resistant to various forces and stresses, even at high cutting speeds. Through fine grinding, the teeth obtain their vertical geometries, which depends on the material to be cut. The effective use of bandsaws for cutting metal requires maximum precision in the tooth geometry. That's a fact – and we know it. That's why, at VOLLMER, we have tried-and-tested solutions that have been specially developed and constructed for these requirements: For grinding tooth tops, straight tooth faces and clearance surfaces on both sides.

And in the last 100 years, we have not just focused on machines, but also on the people who operate them. In order to make work as easy, safe and pleasant as possible, we abide by the VOLLMER operating concept: Intuitive and logical.

THE MOST IMPORTANT ADVANTAGES OF OUR SAW BLADE GRINDING MACHINES:

- Compact design

- Sturdy machine structure for precise sharpening results

- Easy to maintain due to the separation of the machine compartment and operating area

- Simple operation

- Outstanding grinding finish

- High output and economic efficiency

- Shorter service visits

- Advanced technology

- Optimally adjusted to applications and requirements

Discover the VOLLMER accessories.

Your Contact

115 Enterprise Drive

Pittsburgh, PA 15275

USA

Phone: +1 412 2780655

Fax: +1 412 2780520

info-us@vollmer-group.com