We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

New power pack for the VHybrid 360 VOLLMER machine 2021-03-29

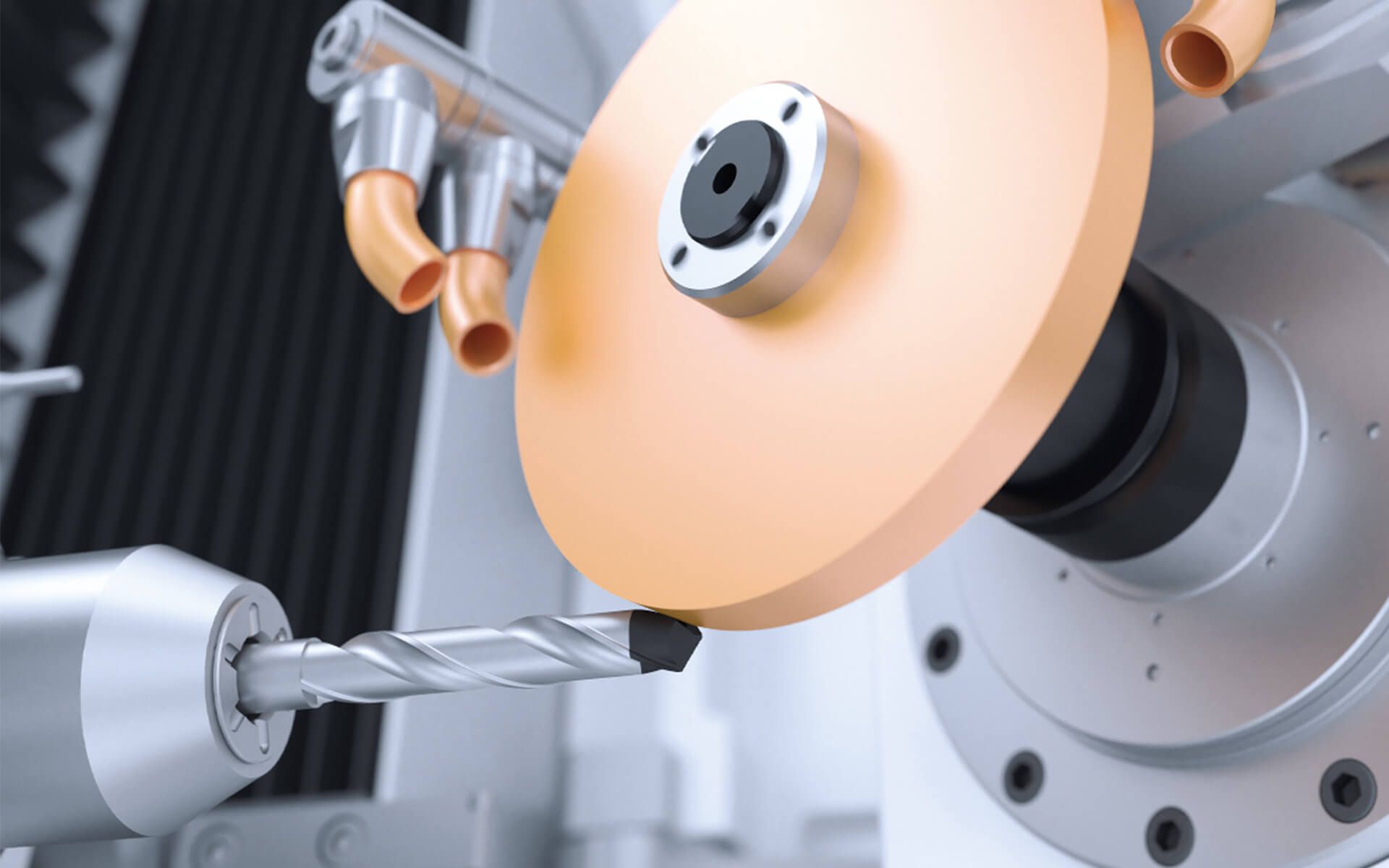

to overviewThe VHybrid 360 a combined grinding and erosion machine from VOLLMER receives more power for machining tools with PCD (polycrystalline diamond). The Swabian sharpening specialist has put together a performance package for eroding. Compared with the standard equipment, the power pack can significantly increase tool-specific efficiency. Through this, VOLLMER is achieving a new benchmark in the area of eroding rotary tooling. The performance package is offered as part of the V@dison initiative and is available as a V@ boost solution via flexible sales and rental models.

The VHybrid 360 grinding and erosion machine fully captures both sharpening processes – grinding carbide tools and eroding PCD tools. This is based on multi-layer machining, which is implemented through two vertically arranged spindles. The upper spindle of the VHybrid 360 is reserved for grinding, while the lower spindle can run both grinding and erosion processes. VOLLMER has created the new performance package specifically for the erosion process, in order to further increase the efficiency of the machine.

"An internal series of tests with PCD-tipped drills has shown that the efficiency of the VHybrid 360 can be immensely increased with the performance package. We are consequently setting new benchmarks in eroding," says Dr Stefan Brand, CEO of the VOLLMER Group. "This allows flexible customer utilization of our V@ boost solution, enabling customers to easily switch between the two packages for particular tools at the press of a button."

The performance increase depends on the parameters of the tool to be machined making the performance package completely flexible in its structure. If the user wants to use it for a specific tool, they switch it on and then simply switch it off again in the same way when they are finished completely within the tool program. Depending on the invoicing model, users can variably adapt the solution to their requirements according to the pay-per-use principle or acquire with a one-off investment within the purchase of the machine.

In general, the VHybrid 360 is suitable for the production of different cutting tools, which are used for machining processes with materials such as wood, metal or composite materials. Thanks to various automations, the VHybrid 360 enables unmanned machining of carbide and diamond tools around the clock. In addition, up to eight grinding and eroding wheel packages including coolant supply can be switched fully automatically.

"Our customers get a free allocation of 100 hours, in order to put the performance package through its paces," says Jürgen Hauger, CEO of the VOLLMER Group. "Furthermore, we are by our customers' side with further services such as training, financing or maintenance, so that they can derive maximum benefit from our machines for their individual tool machining."

Your Contact

VOLLMER UK LTD.Town Street, Sandiacre

Nottingham NG10 5BP