We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

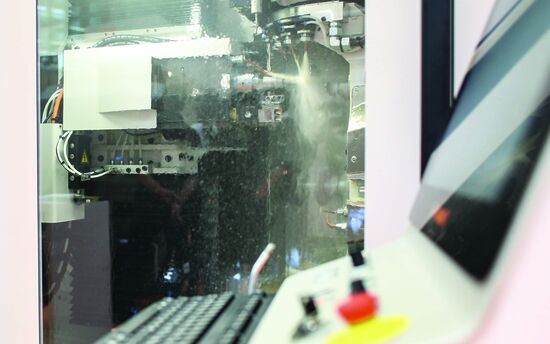

VGrind infinity LINEAR Highly flexible grinding machine for the efficient machining of precision tools.

STABLE WALL CONCEPT

The extremely rigid and compact construction is the result of temperature-stable polymer concrete foundation. This offers the operator optimal accessibility and work area visibility with unparalleled process stability.

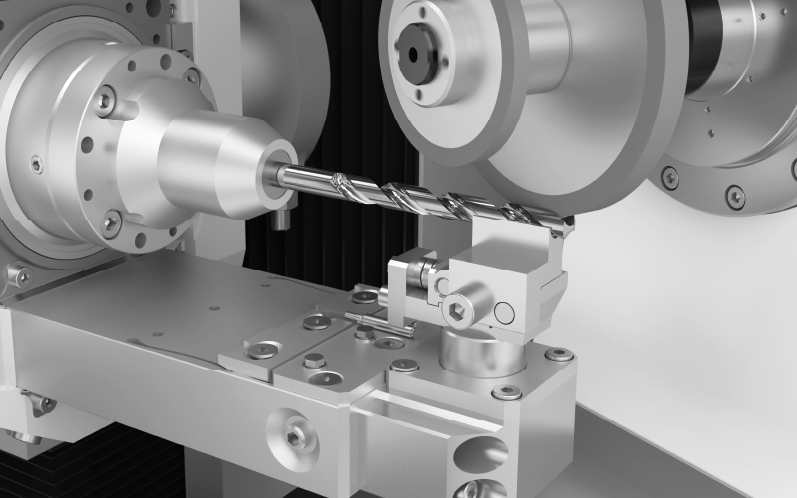

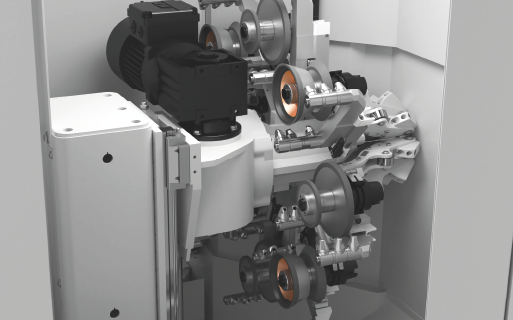

MULTI-LEVEL MACHINING

With the ground-breaking double vertical grinding spindles where the grinding wheels are located at the C axis pivot point, the kinematics reduce machining times with shorter linear-axis travel distances.

INCLUDING IOT GATEWAY

The keyword is Industry 4.0: Our machines are enabled with an IoT gateway that is fitted as standard. This opens the door to the digital world for your business.

COOLING CONCEPT

The plate heat exchanger guarantees effective and sustainable cooling of the torque motors and the grinding spindles. And the best part? No additional chiller unit is required.

INTUITIVE NUMROTO CONTROL SYSTEM

The tried-and-tested software provides a complete 3D tool and machine simulation, combined with unsurpassed collision monitoring for complete process control.

Limitless in versatility. uncompromising in precision.

The VGrind infinity sets new standards in the machining of precision tools. It effortlessly handles a wide range of tool sizes, types, and materials while consistently delivering top-tier quality. Thanks to its unique machine concept and tailored automation solutions, the VGrind infinity is more than just a grinding machine – it’s a true all-rounder. Don’t settle for limits – choose maximum flexibility and tackle every challenge, from standard tools and microtools to custom-made special solutions.

ULTIMATE PRECISION

An innovative kinematic system with multi-level machining at the pivot point of the C axis, wear-free linear motors on the X, Y, and Z axes, and exceptional machine rigidity make the VGrind infinity a true success factor for your production processes. This is further enhanced by an intelligent cooling concept with a plate heat exchanger that ensures perfect thermal stability – entirely without a cooling unit. The result: minimal tolerances and maximum precision thanks to optimal cooling.

MAXIMUM EFFICIENCY

Efficiency at every level – that’s the promise of the VGrind infinity. Every component of the machine is designed to significantly boost productivity. Many features have been completely reimagined. The result: less downtime, more output – with the clear goal of giving you a decisive competitive edge.

UNLIMITED FLEXIBILITY

Machining delicate microtools and large tools made from a wide variety of cutting materials on a single machine – all without the slightest compromise in quality? The VGrind infinity by VOLLMER makes this possible. With thoughtful solutions down to the finest detail and a flexibility that sets new standards. Want an example? The individually configurable spindles provide exactly the required speed and torque for each tool and cutting material. For limitless freedom in machining.

READY FOR THE FUTURE

Automatically boost your productivity with flexible automation solutions – whether overnight or over the weekend – 24/7. Additionally, an IoT gateway is included as standard, enabling data flow between the machine and the digital environment. Optimize your processes, avoid errors, and minimize downtime.

GREATEST VARIETY.

From microtools starting at 0.2 mm to tool diameters of 200 mm – the VGrind infinity masters every dimension with unparalleled precision. It effortlessly handles fully cylindrical tools up to 32 mm in diameter. And with tool lengths up to 360 mm*, it fully unleashes its potential. For uncompromising quality in every size.

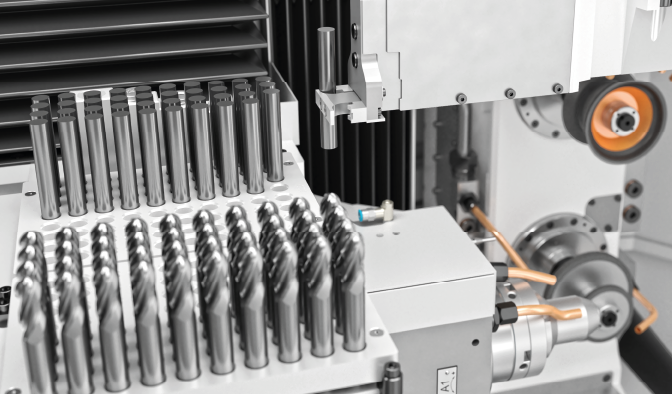

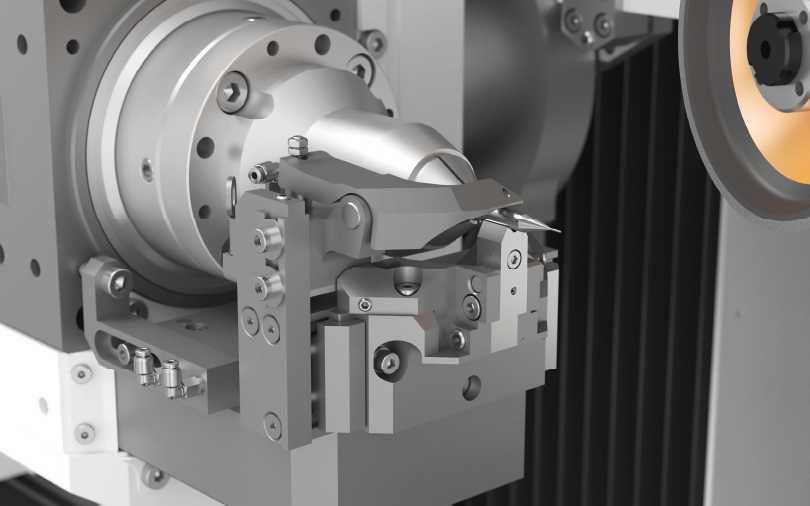

UNIQUE KINEMATICS.

Two vertically arranged grinding spindles, combined with a grin - ding wheel set positioned at the pivot point of the C axis, ensure maximum precision and efficiency. The key advantage: the vertical spindle arrangement eliminates the typical fixed and floating bearing issues commonly found in horizontally mounted grinding spindles. This results in a significant improvement in accuracy during the grinding process. And the best part: thanks to individually configurable spindles, speeds and power can be precisely adapted to your specific processes. The optimized gear ratio ensures consistent torque output – delivered by a compact motor that elevates both performance and energy efficiency to a new level.

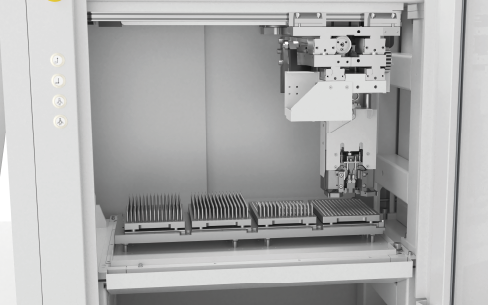

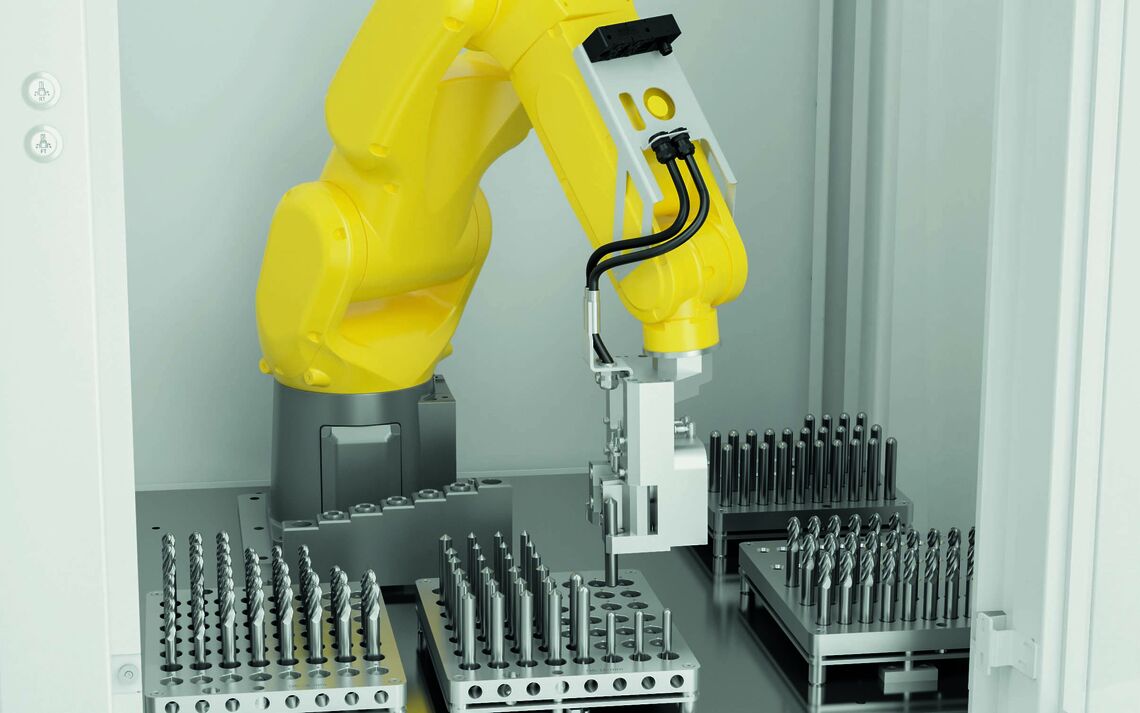

TOOL AUTOMATION

In modern tool production, automation is the key to success – and the VGrind infinity is your gateway to future-proof manufacturing. Whether you’re producing small batch sizes with varying tool diameters or large series, the VGrind infinity offers the flexibility to make your production processes faster, more precise, and safer.

As a true all-rounder in automation, the VGrind infinity provides an impressive selection of options that can be perfectly tailored to your production needs. You can choose from a wide range of configurations and even integrate customized solutions to optimize your manufacturing – all in the smallest of spaces. The standout feature: thanks to its innovative design, external systems can be loaded and unloaded at any time, even during machine operation. This ensures your production runs smoothly – around the clock, 24/7.

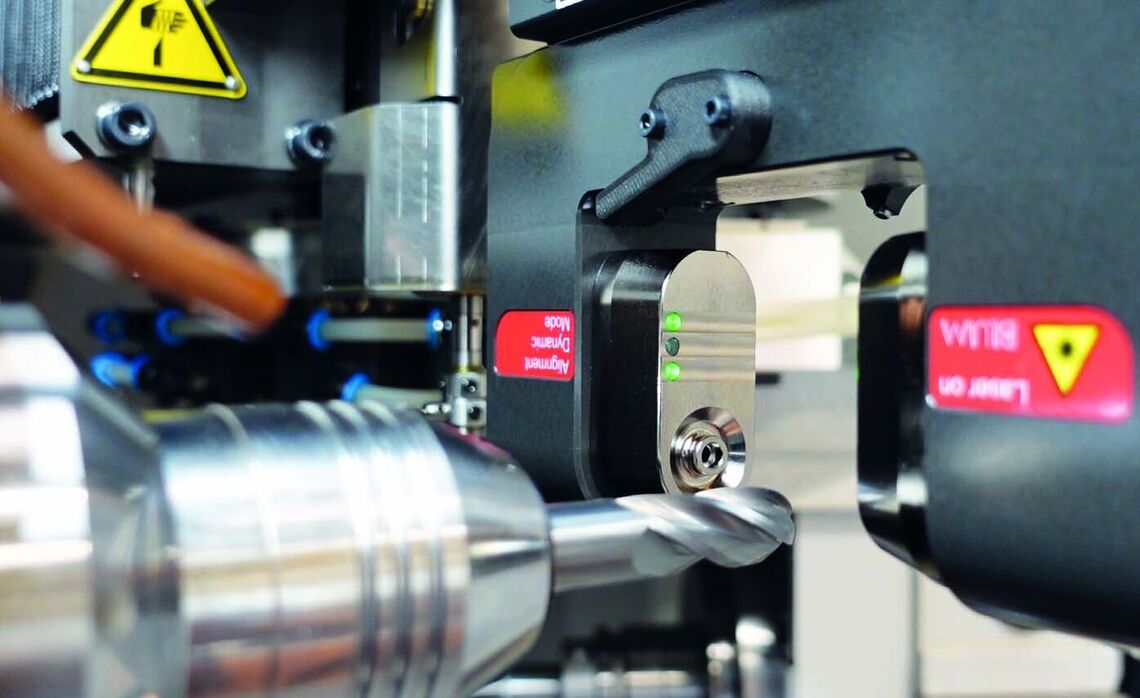

8-Station Grinding Wheel Changer. Steady Rest Systems. Laser Measurement System.

When highest standards meet smart systems, true added value is created – and that’s exactly the idea behind the VGrind infinity. As a high-end grinding machine for tool machining, it not only delivers precision in series, but goes further: toward efficiency, flexibility, and future readiness.

Systems for your added value – that’s our promise. And we deliver on it with intelligent solutions that make a real difference: An 8-station grinding wheel changer for maximum autonomy and tooling versatility. Various steady rest systems that ensure top precision for both short and long tools. And an integrated laser measurement system that guarantees in-process accuracy – fast, reliable, and contactless.

This is how a machine becomes a high-performance complete system – perfectly tailored to your production requirements. Welcome to a new class of tool grinding.

VOLLMER is your partner for demanding challenges.

Every manufacturing requirement is unique – and the VGrind infinity is perfectly equipped for that. With its innovative technology and modular adaptability, it enables precise implementation of customized solutions.

Whether complex geometries, special material requirements, or individual production processes – the VGrind infinity offers maximum flexibility and the highest precision. Thanks to intelligent software solutions, automated processes, and the proven VOLLMER quality, tailor-made manufacturing strategies can be realized efficiently and economically.

VOLLMER is your partner for demanding challenges. With our experience and innovative strength, we work together with you to develop the optimal solution for your specific requirements – precise, reliable, and future-ready.

FAMILIAR FEATURES. REDEFINED.

In the world of grinding technology, there are functions that are wellknown – standards that have become established. However, true innovation begins where the familiar is not simply adopted, but questioned and reimagined. With the VGrind infinity, VOLLMER focuses exactly on this. Functions that are common in many machines are thoughtfully optimized, precisely integrated, and consistently designed for process reliability. The result is not „more of the same,“ but a tangible advancement in the details. For your manufacturing and your competitive edge.

AUTOMATIC PRODUCTION START.

Time loss often occurs before the actual production begins – for example, when machines need to be brought up to operating temperature, and the manufacturing process then has to be started manually. The VGrind infinity handles this step autonomously: it undergoes a defined warm-up program for thermal stabilization within a few minutes and automatically starts the planned production as soon as all operating parameters are within the target range. This not only saves valuable production time but also ensures a quick start and smooth operation – particularly a significant advantage in unmanned operation.

AUTOMATIC TWEAK-IN.

The machine axes are fully calibrated automatically, and the zero point is defined with maximum accuracy. What typically has to be done manually and laboriously on conventional grinding machines after commissioning or during service interventions, the VGrind infinity handles autonomously – upon request and at any time.

The result: perfect symmetry, maximum process reliability, and consistently precise grinding results. For those who don’t want to make any compromises.

Your Contact

115 Enterprise Drive

Pittsburgh, PA 15275

USA

Phone: +1 412 2780655

Fax: +1 412 2780520

info-us@vollmer-group.com