We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

MODERN OPERATING CONCEPT

Height-adjustable touch screen interface with 19" screen and ergonomic design for optimal view of the work area.

WALL CONCEPT

Very rigid, compact construction with exceptional access and view of the work envelope.

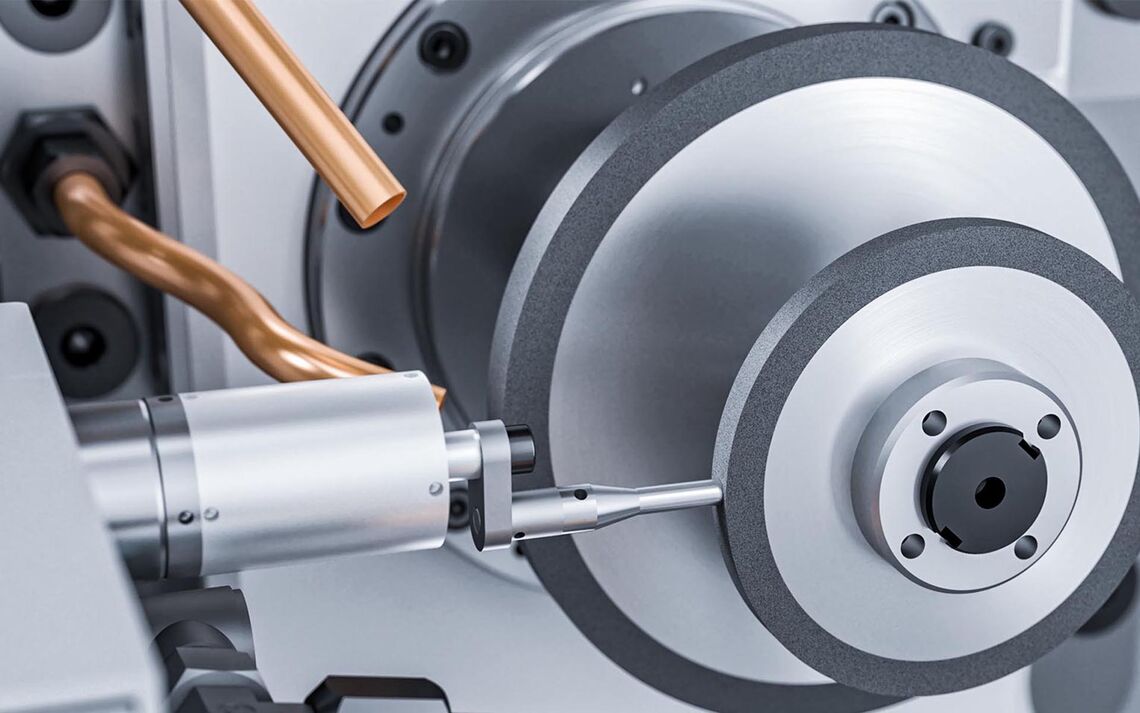

MULTI-LAYER MACHINING

Two vertically positioned grinding spindles with the grinding wheel at the C axis pivot point. Reduced machining times thanks to shorter linear-axis travel distances.

INCLUDES IOT GATEWAY

The hot topic of Industry 4.0: Our machines are ready to communicate. An IoT gateway is installed as standard to provide central machine data acquisition.

NUMROTOplus®

Reliable and intuitive software platform with 3D tool and machine simulation that combines collision monitoring.

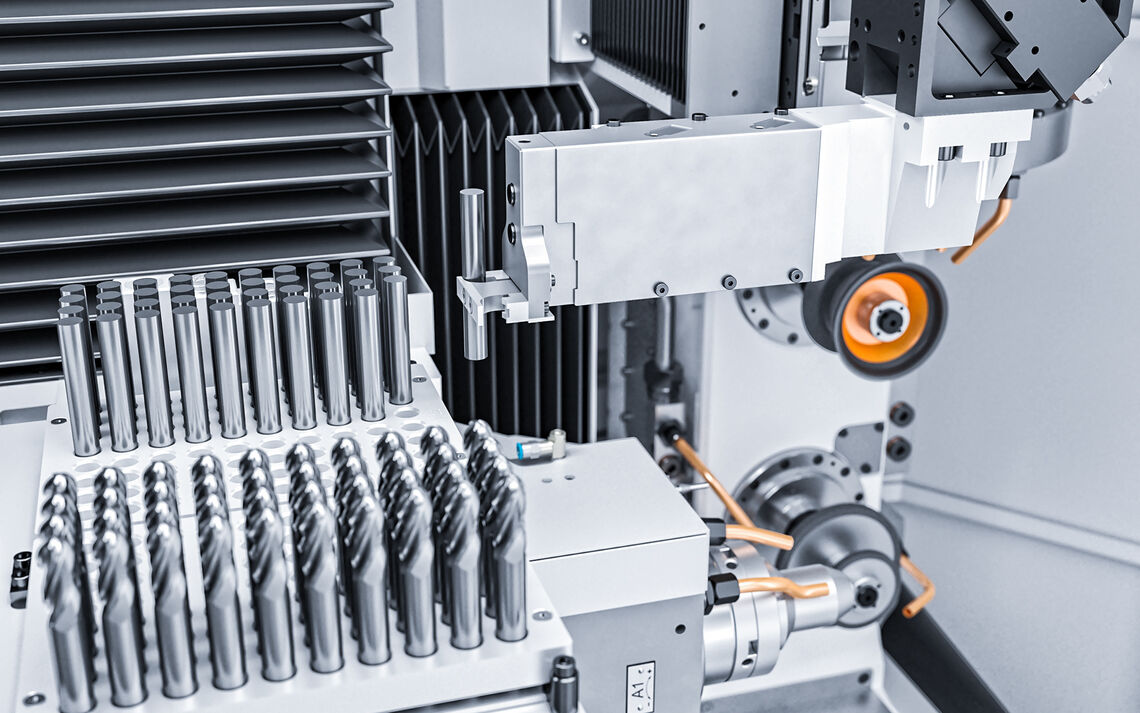

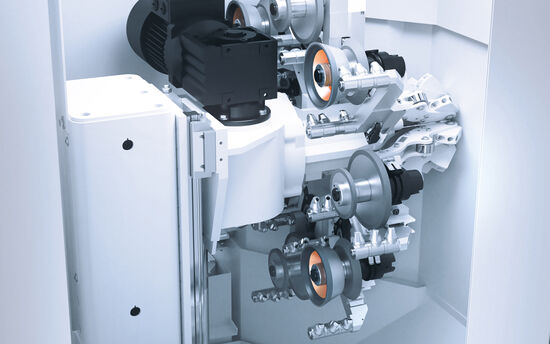

GRINDING-WHEEL CHANGER

Provides greater manufacturing flexibility – with up to eight grinding wheel packages.

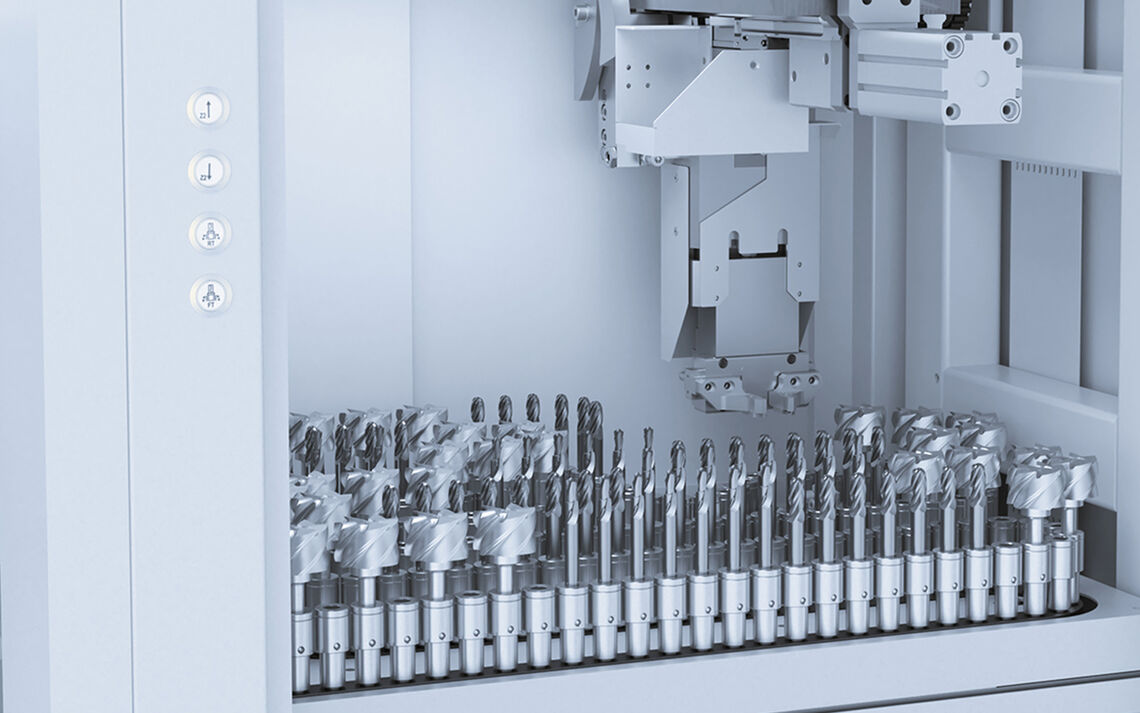

AUTOMATION

The VOLLMER HP 160 pallet magazine, the HC 4 chain magazine, or the internal pallet loader automatically ensures increased capacity and flexibility.

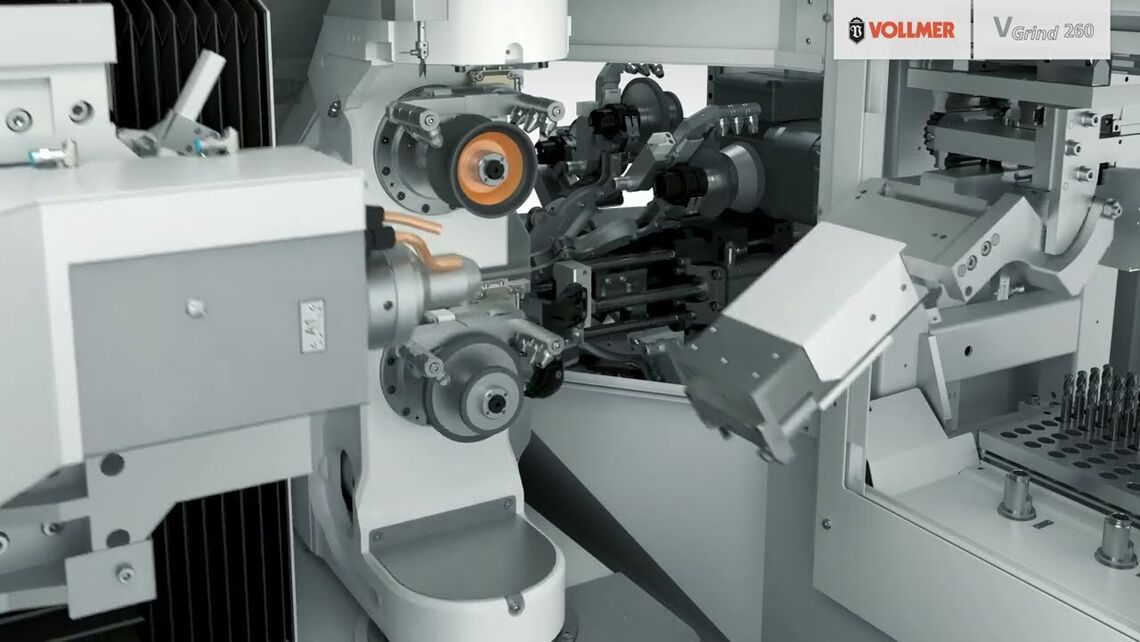

DOUBLE SPINDLES FOR HIGH EFFICIENCY.

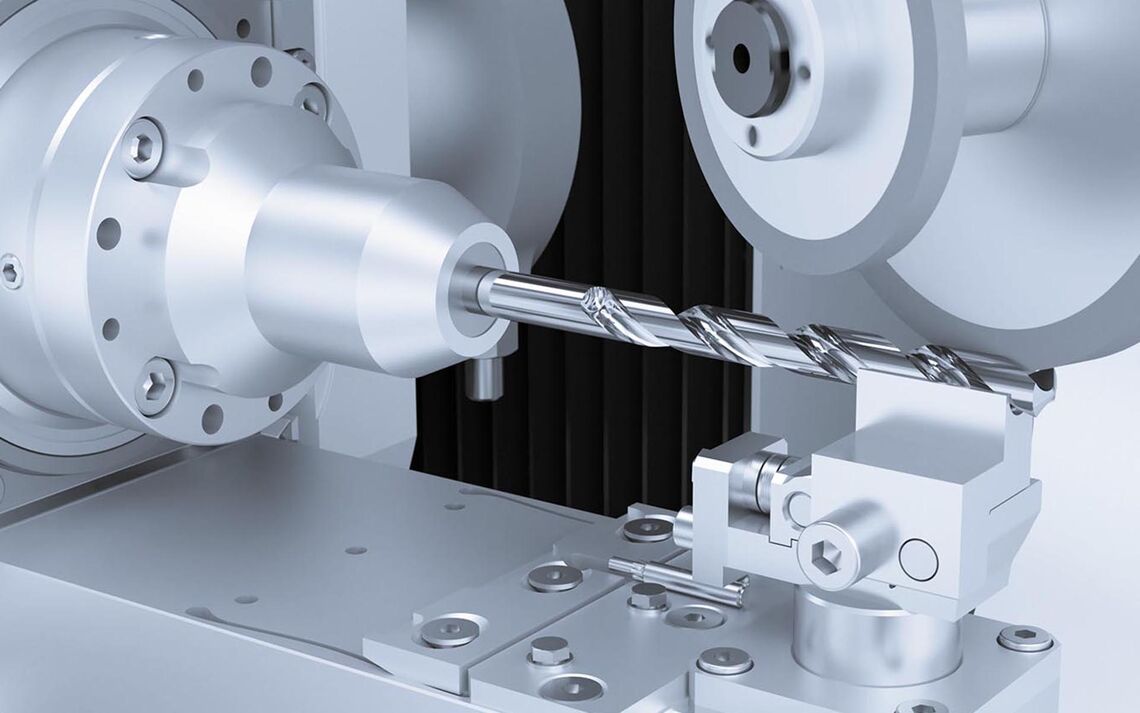

The VGrind 260 has everything you could possibly need for the complete machining of your rotary tools. Ideal for sectors such as the automotive engineering, tool making, medical technology, precision engineering and aerospace industries.

The VGrind 260 is equipped with tried-and-tested kinematics and a double spindle. Delivering precision multi-layer machining and the best thing about the VGrind 260 is that you can configure the machine to meet your specific requirements

From automation and coolant distribution to configuring the spindles and much, much more – configure your machine to work exactly how you want. The VGrind 260 offers a new world of possibilities..

VGrind 260 – INDIVIDUALLY CONFIGURABLE.

THE APPLICATION

VGrind 260 - MAXIMUM PRECISION

The VGrind 260 has been designed for the efficient machining of rotary tools with different diameters.

The ability to change both grinding wheel packages and integrate a range of automation options provides the highest possible flexibility with reduced changeover times – perfect for flexible high-quality grinding.

THE MACHINE CONCEPT

The proven principle of vertically aligned grinding spindles has been brought to the VGrind 260. The efficient cooling concept has also been optimised. The result is perfection – the lowest tolerances with the most efficient cooling technology.

- Five-axis CNC grinding machine with innovative kinematics

- Two grinding spindles positioned one above the other with the grinding wheels positioned at the C axis pivot point – this ensures extremely precise grinding results

- The two vertically positioned grinding spindles eliminate known concerns of using a floating bearing as opposed to a single spindle with two ends

- Innovative wall concept and polymer concrete base provide the highest possible rigidity and outstanding damping characteristics

- The VGrind 260 plate heat exchanger guarantees effective, long-term cooling of the motors and grinding spindles. Even better – No additional chiller unit is required

- Both grinding spindles can be equipped with a variety of grinding wheel packages. The automation option ensures seamless grinding wheel changes, every time!

- Flexible automation options for rotary tools

- Grinding spindle available with direct or belt drive

- Automatic changing of grinding wheel packages complete with coolant elements for optimum productivity

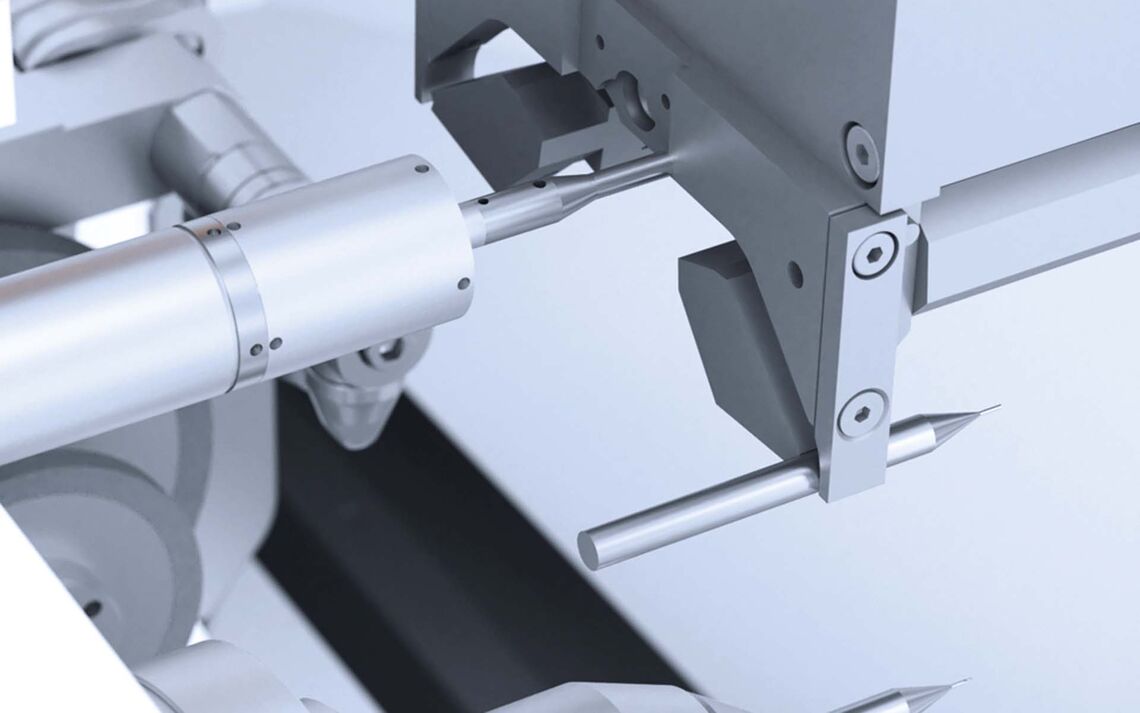

- The automatic handling mechanism compensates positioning during the process to ensure maximum precision when loading and unloading tools and reduction sleeves. This reduces wear and optimises concentricity

- The wheel measuring probe provides grinding wheel measurement and wear control all within the machine and process

- Automated changing of intermediate sleeves with bayonet

- Automatic sticking unit enables the grinding wheel to be opened during production

- Simultaneous grinding wheel package and tool change in combination with the HP 160 pallet magazine or the HC 4 shortens non-productive times during loading

- Stable, fully adjustable steady rest with automatic stroke ensures optimal grinding results

THE OPERATING CONCEPT

Thanks to its simplified, intuitive operation, the VGrind 260 ensures that you always have everything under control. The height-adjustable desk features a clear LCD display, which is ergonomically positioned to provide operators with a good view of the work area at all times. During operation, you can choose to use the keyboard, touch screen or both – whichever is right for you.

The manual operating unit ensures even more flexibility: It can be freely positioned on the enclosure and is designed for setting individual axes – without using the control panel.

In short, the VGrind 260 has been optimally designed with ergonomics and intuitive operation in mind – for your benefit. It makes it easy for you to achieve the best possible results.

ERGONOMIC OPERATION

- Flexible

- Height-adjustable and tilting control desk,

- Versatile manual operating unit

- Optimal view of the machine

- Simple access to the grinding spindles

It doesn't get more flexible than this.

Software NUMROTOplus®

VOLLMER consciously decided on a well-known system that is already established on the market. The logically structured interface guarantees intuitive operation. With an established programming system, a huge variety of tools can be manufactured and resharpened. You can change any detail of your tools and adapt them to your individual requirements.

Fully informed: with comprehensive 3D simulation of the tool and machine and with collision monitoring, you can be confident of complete process control.

V@dison: DIGITAL SOLUTIONS – PRECISION IN TRANSFORMATION

Do you want to optimise your processes with smart technologies, avoid mistakes and reduce downtimes? We offer grinding and sharpening machines that are equipped with an IoT gateway as standard. Contact your VOLLMER representative or find out more now at:

www.vollmer-group.com/en/products/digitalisation

AUTOMATION

Work process automation is one of the key factors of modern tool machining. With the VGrind 260, you can choose from a range of excellent equipment options. This allows you to implement different batch sizes for your tools and to make your manufacturing processes quicker, safer and more precise.

The various automation options that we offer enable you to optimally adjust the VGrind 260 to your requirements.

- HP 160 pallet magazine with compact pallets (for up to 900 blanks or tools) and double gripper to guarantee quick changing times

- The HC 4 chain magazine has space for 158 shank-type tools or, alternatively, up to 39 HSK-A63 tool holders in a compact design

- Also available with an internal pallet loader to provide space for two compact pallets with a capacity of up to 300 blanks or tools. Alternatively, chaotic loading of different tool shank diameters is also possible

With the eight-station grinding-wheel changer, you automatically have the correct grinding wheel available. If required, this can also include interchangeable coolant elements on both grinding spindles. This helps to increase productivity in your manufacturing facility and reduce changeovers.

An oriented spindle stop function positions the grinding wheel packages in the same location on the grinding spindle. This reduces run-out errors and therefore increases precision.

Your Contact

Josef-Loroch-Str. 1

69509 Mörlenbach

Germany

Phone: +49 6209 71590

Fax: +49 6209 715938

info@loroch.de