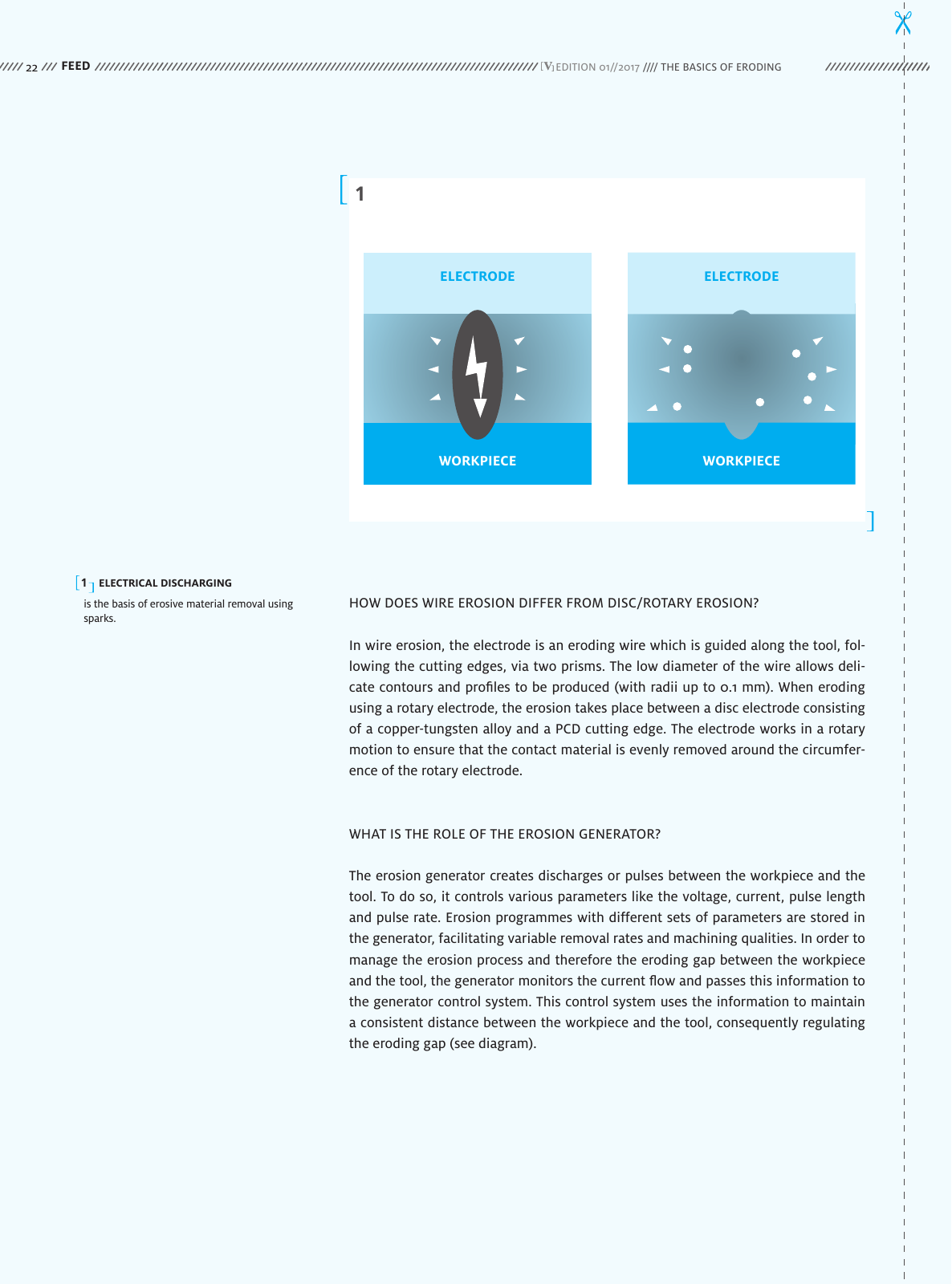

11 ELECTRICAL DISCHARGING is the basis of erosive material removal using sparks HOW DOES WIRE EROSION DIFFER FROM DISC ROTARY EROSION In wire erosion the electrode is an eroding wire which is guided along the tool fol lowing the cutting edges via two prisms The low diameter of the wire allows deli cate contours and profiles to be produced with radii up to 0 1 mm When eroding using a rotary electrode the erosion takes place between a disc electrode consisting of a copper tungsten alloy and a PCD cutting edge The electrode works in a rotary motion to ensure that the contact material is evenly removed around the circumfer ence of the rotary electrode WHAT IS THE ROLE OF THE EROSION GENERATOR The erosion generator creates discharges or pulses between the workpiece and the tool To do so it controls various parameters like the voltage current pulse length and pulse rate Erosion programmes with different sets of parameters are stored in the generator facilitating variable removal rates and machining qualities In order to manage the erosion process and therefore the eroding gap between the workpiece and the tool the generator monitors the current flow and passes this information to the generator control system This control system uses the information to maintain a consistent distance between the workpiece and the tool consequently regulating the eroding gap see diagram WORKPIECE WORKPIECE ELECTRODE ELECTRODE EDITION 01 2017 THE BASICS OF ERODING22 FEED

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.