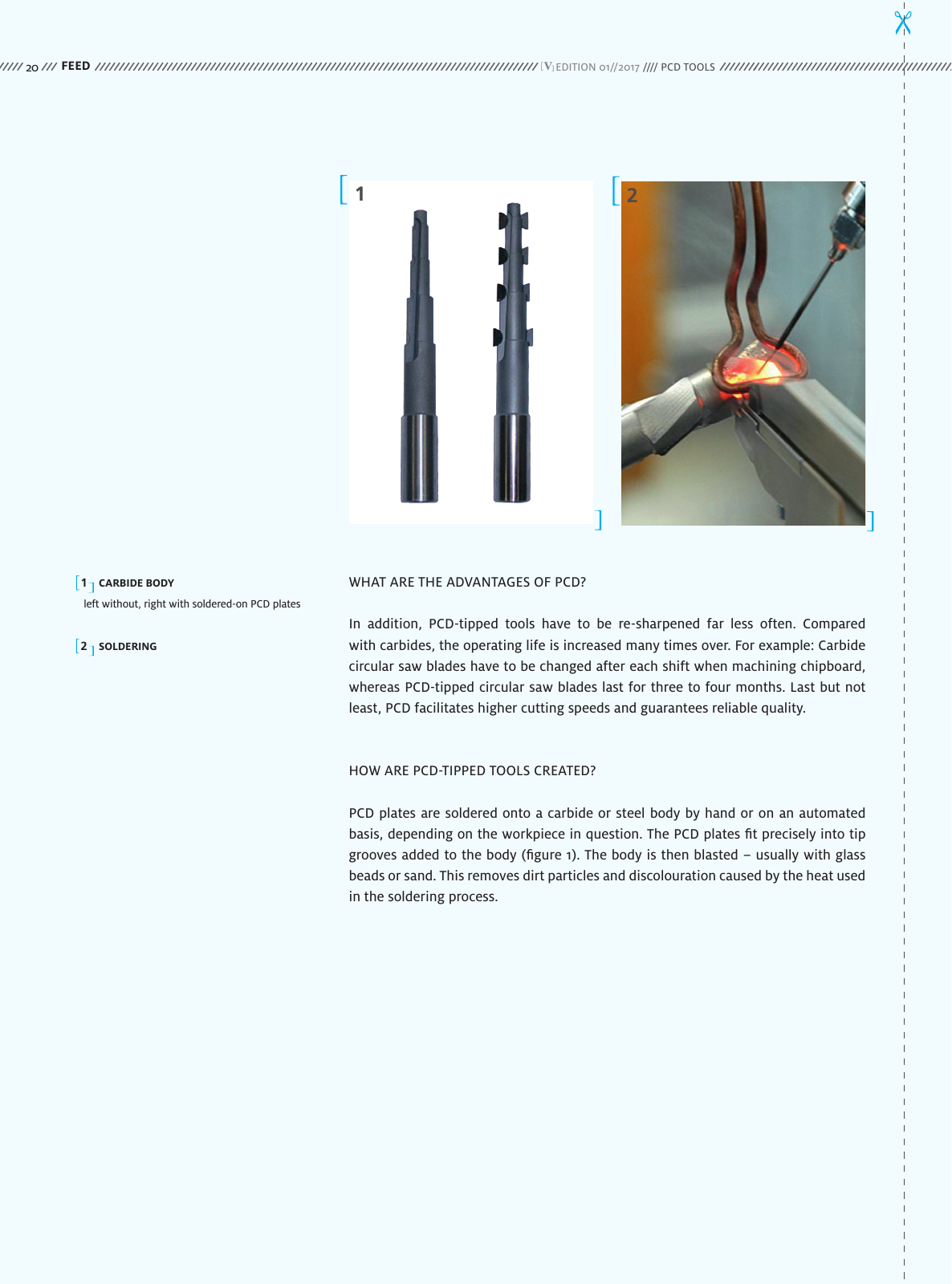

WHAT ARE THE ADVANTAGES OF PCD In addition PCD tipped tools have to be re sharpened far less often Compared with carbides the operating life is increased many times over For example Carbide circular saw blades have to be changed after each shift when machining chipboard whereas PCD tipped circular saw blades last for three to four months Last but not least PCD facilitates higher cutting speeds and guarantees reliable quality HOW ARE PCD TIPPED TOOLS CREATED PCD plates are soldered onto a carbide or steel body by hand or on an automated basis depending on the workpiece in question The PCD plates fit precisely into tip grooves added to the body figure 1 The body is then blasted usually with glass beads or sand This removes dirt particles and discolouration caused by the heat used in the soldering process 1 2 1 CARBIDE BODY left without right with soldered on PCD plates 2 SOLDERING EDITION 01 2017 PCD TOOLS20 FEED

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.