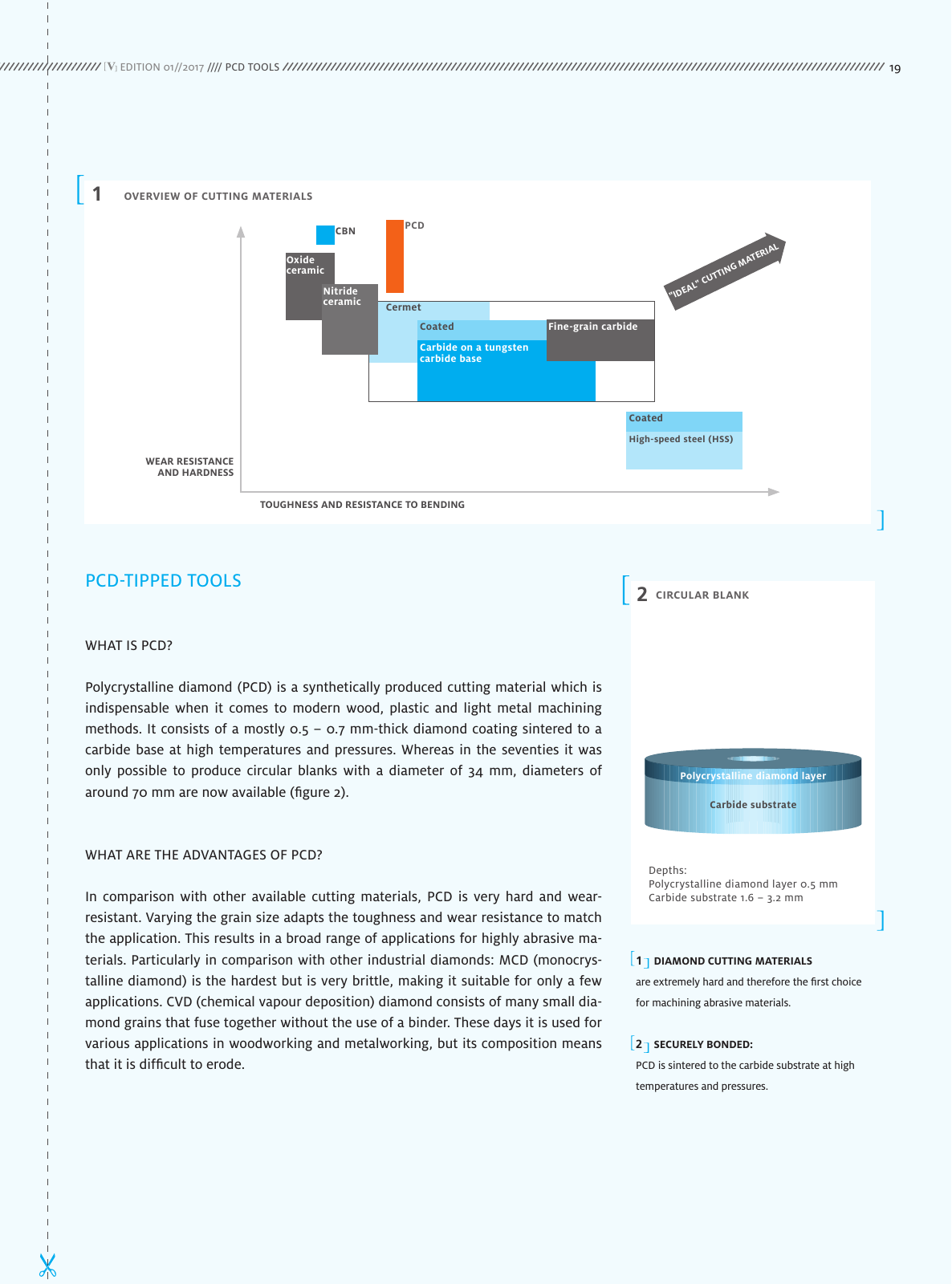

2EDITION 01 2017 PCD TOOLS PCD TIPPED TOOLS WHAT IS PCD Polycrystalline diamond PCD is a synthetically produced cutting material which is indispensable when it comes to modern wood plastic and light metal machining methods It consists of a mostly 0 5 0 7 mm thick diamond coating sintered to a carbide base at high temperatures and pressures Whereas in the seventies it was only possible to produce circular blanks with a diameter of 34 mm diameters of around 70 mm are now available figure 2 WHAT ARE THE ADVANTAGES OF PCD In comparison with other available cutting materials PCD is very hard and wear resistant Varying the grain size adapts the toughness and wear resistance to match the application This results in a broad range of applications for highly abrasive ma terials Particularly in comparison with other industrial diamonds MCD monocrys talline diamond is the hardest but is very brittle making it suitable for only a few applications CVD chemical vapour deposition diamond consists of many small dia mond grains that fuse together without the use of a binder These days it is used for various applications in woodworking and metalworking but its composition means that it is difficult to erode 1 DIAMOND CUTTING MATERIALS are extremely hard and therefore the first choice for machining abrasive materials 2 SECURELY BONDED PCD is sintered to the carbide substrate at high temperatures and pressures 1 Depths Polycrystalline diamond layer 0 5 mm Carbide substrate 1 6 3 2 mm Polycrystalline diamond layer Carbide substrate CIRCULAR BLANK OVERVIEW OF CUTTING MATERIALS TOUGHNESS AND RESISTANCE TO BENDING WEAR RESISTANCE AND HARDNESS Oxide ceramic Nitride ceramic Cermet ID EAL CU TTIN G M ATE RIA L CBN PCD Fine grain carbideCoated Coated High speed steel HSS Carbide on a tungsten carbide base 19

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.