We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Products

Images and captions may only be used within the scope of editorial reporting on VOLLMER. These can be used free of charge, provided that the source reference "VOLLMER WERKE Maschinenfabrik GmbH" is cited and a free copy of the publication is sent to VOLLMER WERKE Maschinenfabrik GmbH, Marketing Services, Ehinger Strasse 34, D-88400 Biberach/Riss.

Changes to the images are not permitted. The corporate images have a resolution of 300 dpi. All images are provided in the RGB colour space (sRGB IEC61966-2.1). Conversion to the CMYK colour space for the respective production process must be performed by your pre-press.

VOLLMER industry expertise in circular saws

VOLLMER has a uniquely diverse portfolio of high-performance, advanced machines for maintaining and sharpening circular saws. Whether for tool production, chipping saw mills or a sharpening service, VOLLMER has the right solution for your specific needs.

1.2 MB

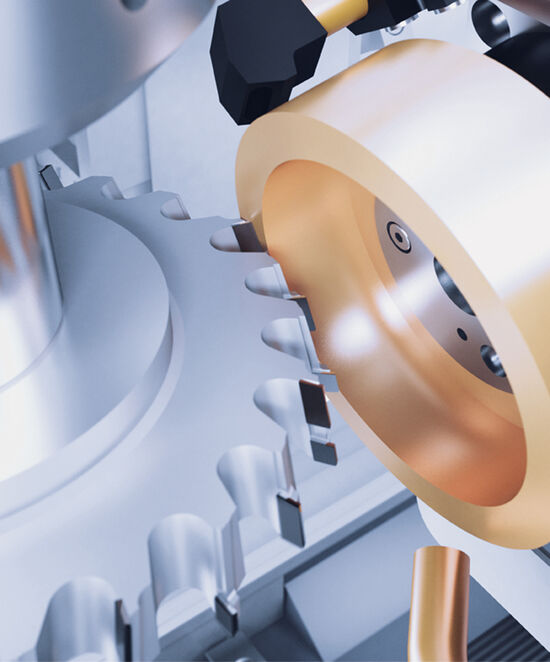

VOLLMER CP 650

The CP 650 sharpening machine is suitable for machining carbide-tipped circular saw blades with different tooth geometries on the tooth faces and tooth tops up to a diameter of 650 mm.

680 KB

VOLLMER CP 650 in detail 1

The CNC-controlled CP 650 with multiprocessor technology is designed for machining the tooth faces and tooth tops on carbide-tipped circular saw blades. All common tooth geometries for wood and aluminium machining are stored as standard.

300 KB

CM 300 b 12 28 web

With the fully automatic CM 300 sharpening machine carbide-tipped circular saw blades can be specially sharpened for the metal machining industry up to a diameter of 1440 millimetres.

27 KB

VOLLMER CM 300 in detail

The CM 300 fully sharpens the tooth geometry of hook and clearance angles on carbide-tipped circular saw blades for metal machining without the saw blades having to be clamped in more than one position.

743 KB

VOLLMER industry expertise in PCD rotary tools

Whether in the automotive, air or aerospace industry, whether aluminium, magnesium or MMX, wherever state-of-the-art PCD tools are used, VOLLMER has the right solutions: For highly efficient and accurate machining with wire or disc erosion machines.

1.2 MB

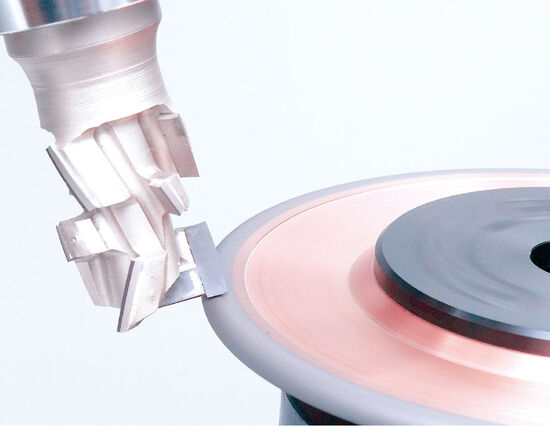

VOLLMER QXD 250

The all-round genius for eroding: The QXD 250 disc erosion machine has six simultaneously controlled CNC axes. This enables complete machining, including measurement, eroding, grinding, and polishing, without the saw blades having to be clamped in more than one position. With the new Vpulse EDM erosion generator, the VOLLMER QXD 250 erosion machine can machine PCD-tipped tools up to 30 percent faster.

1.3 MB

VOLLMER QXD 250 in detail 1

The Vpulse EDM erosion generator sets the pace in the VOLLMER QXD 250 erosion machine – up to 30 per cent faster and with a surface finish that is three times more refined.

1.2 MB

VOLLMER QXD 250 in detail 2

The most diverse range of tools, such as end mills in the wood industry and further machining tools, can be produced with the QXD 250 in large batch sizes and without manual intervention.

1.2 MB

VOLLMER services: Spare parts 1

VOLLMER consumables are perfectly matched to the sharpening and erosion machines and increase the availability and service life of VOLLMER machines.

1.5 MB

VOLLMER services: Spare parts 2

Original VOLLMER spare parts comply 100 % with VOLLMER's high quality standards. This is demonstrated by the VOLLMER logo.

1.6 MB

Your Contact

VOLLMER WERKE Maschinenfabrik GmbH88400 Biberach/Riß

Germany