We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

QXD 250 – WELL-POSITIONED FOR EVERY CHALLENGE

Can you improve on perfection? The new VOLLMER QXD 250 has the answer. With an overall concept refined in many aspects and amazing innovations:

- Simultaneous path interpolation along six CNC-controlled axes – including the new A-axis

- Extended travel distances and swivel ranges for tool diameters up to 320 mm and tool lengths up to 250 mm

- Redesigned main spindle drive for efficient grinding

- VPulse EDM, the optimum technology for any processing objective

- Extensive options for flexible adjustment to the specific requirements in the metal or wood tools sector

- Complete machining in one clamping operation – from measuring to erosion and from grinding to polishing

V@ dison combines our new, digital services and offers from the V@ screen, V@ check, V@ boost and V@ guide ranges.

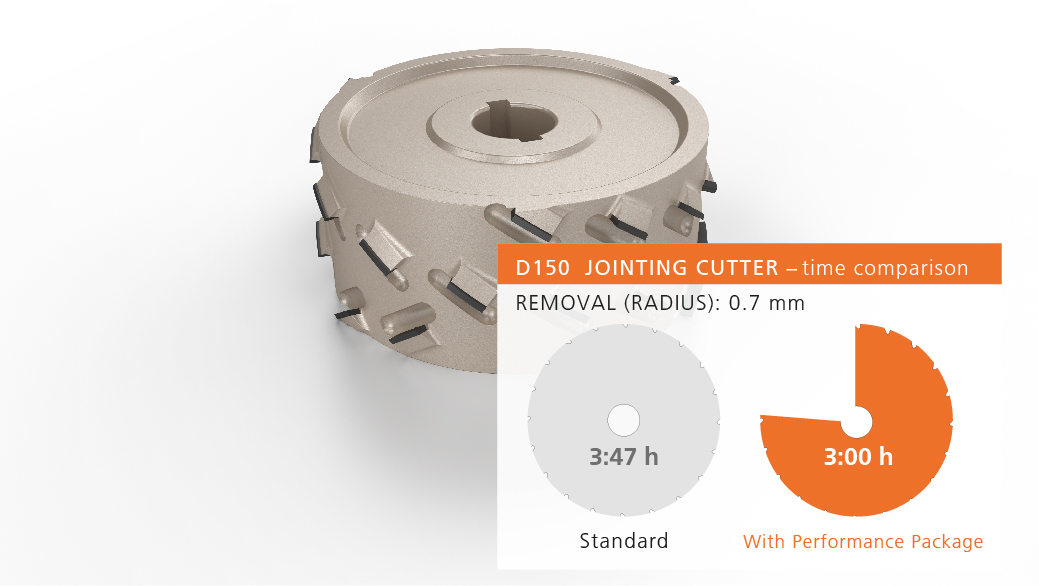

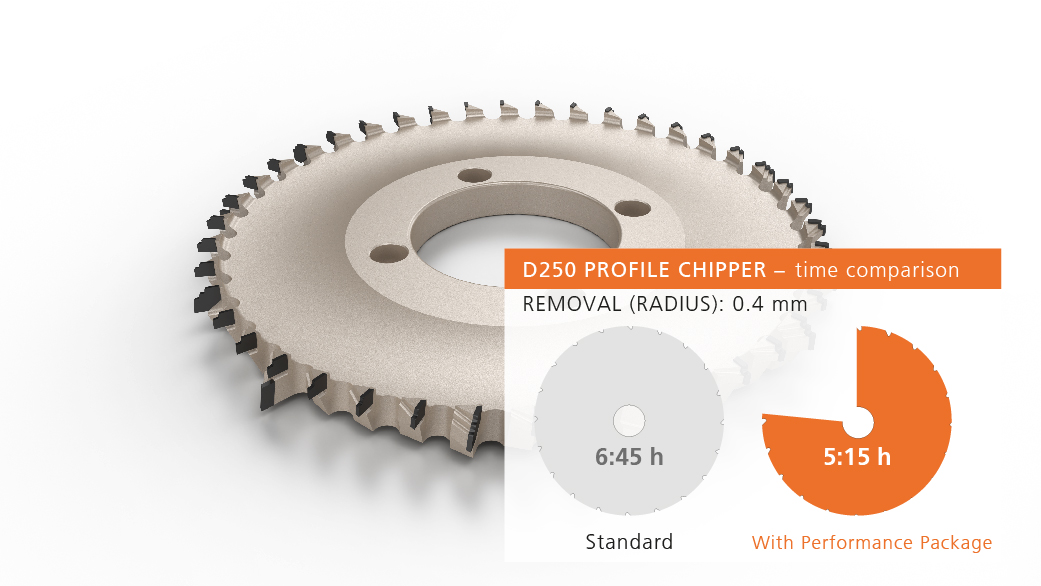

With the performance package for the QXD 250, we present a highly functional product in the V@ boost range. As with all future V@ boost products, it is designed to exploit potential consistently and fully. The performance package optimises the machining processes for PCD tools and, as a result, expands the scope of functions of the QXD 250 erosion machine.

PERFORMANCE PACKAGE

MORE EFFICIENT, MORE ECONOMICAL, FLEXIBLE TO USE.

Our eroding machines have another ace up their sleeve when it comes to efficiency. They can draw on additional power when eroding where appropriate. Use the performance packages for this, currently for the QXD 250 and VHybrid 260 in particular. Depending on the tool geometry and your machining requirements, the use of the performance package can ensure that the machining time is additionally reduced and, therefore, guarantee a significant increase in efficiency for the machine.

However, the performance increase depends on the parameters of the tool to be machined. The performance package is, therefore, completely flexible. If the user wants to use it for a specific tool, they switch it on and then simply switch it off again in the same way when they are finished. The billing model can be flexibly adapted by the customer to their needs via an hourly quota.

PATH PROGRAM 360

Technological advancement never stops – and that is especially true of the software sector. VOLLMER specialists are continually further developing applications and adapting these to your tasks and requirements. Our software updates therefore ensure that your VOLLMER machine is always up-to-date. The range of services provided by your machine is thus permanently being extended, its flexibility improved in the long-term and your manufacturing process kept at the highest level.

With the further-developed HP 360 software package, it couldn't be easier to use new functions of your QXD 250 or improve existing ones.

- Integrated three-point measurement

- Integrated cup wheel functionality

The main benefits for you at a glance:

- Quality: Better axial run-out and concentricity due to increased precision when measuring

- Efficiency: Greater production capacity due to shorter measuring times of sometimes over 30%

- User-friendliness: Increased flexibility when programming and expanded functionalities

AUTOMATION

Do you want extremely efficient and productive machining of your PCD rotary tools? Without compromising the quality of results? No problem! The QXD 250 is already optimally equipped for automation. For unmanned shifts round the clock – and therefore maximum efficiency. Whether you prefer the fully automated changing of tools or of eroding wheels. Or both. You have the choice.

TOOL CHANGER

The right tool is ready every time: The integrated tool changer for up to six different erosion, grinding and polishing discs enables perfect implementation of numerous workpiece variants.

WORKPIECE STORAGE

An essential component of your automated machining is the right external tool storage. VOLLMER offers you three tried-and-tested solutions here – from a chain magazine to a round magazine:

With HC 5 and HC 11, you have two different workpiece storage solutions to choose from. They provide space for up to 28 or 64 workpieces respectively. They can be loaded and unloaded during machining – without delay. That is VOLLMER efficiency.

The new double-layered HR holds up to 30 tools in the smallest of spaces – thanks to two levels positioned on top of each other. It enables the automatic machining of tools with different diameters of up to 320 mm. For greater capacity and flexibility.

THE APPLICATION

Whether wood or metal machining, tool manufacturing or maintenance, VOLLMER is familiar with the special challenges they all present on a daily basis. The new QXD 250 can therefore be flexibly adjusted to suit your needs.

WOOD

Speed, efficiency and productivity are top priority for those who want to successfully produce and machine tools for woodworking. VOLLMER has the ideal solution for this too: The new QXD 250.

- Workpiece diameter of up to 320 mm

- Workpiece weight of up to 25 kg

- Extended swivel range of B-axis up to ± 20° for maximum clearance at the workpiece

- Redesigned main spindle drive for optimum grinding operations

METAL

During the manufacture and maintenance of sophisticated and highly complex metal tools, the utmost precision and the greatest flexibility are required. In order to give you the best possible support, we then developed the new QXD 250.

- VPulse EDM technology for the best surfaces up to 0.1 μRa

- Workpiece lengths up to 250 mm

- Extensive options to enhance machine functionality, e.g. polishing or drill machining

THE OPERATING CONCEPT

VOLLMER experts know: With the unique VOLLMER operating concept, even complex machining tasks are accomplished quickly, safely and reliably after only a brief training period. Thanks to clear VOLLMER symbols, intuitive programming is possible. The Windows-based interface also ensures a minimum risk of operator input error thanks to easy to understand graphical representations. A consistently high quality is therefore guaranteed at all times.

EXLEVEL PRO – INCREASED DIVERSITY. INCREASED FLEXIBILITY. INCREASED SAFETY.

- ExLevel PRO offers a comprehensive range for the manufacture and maintenance of PCD drilling and PCD milling tools.

- With the combination of eroding and grinding processes (hybrid machining), complete machining can be even more comprehensive.

- Many processing types, previously only used with solid carbide, can now be adapted for the manufacture of PCD tools.

- Modular design: Demand-driven installation according to the application range.

QXD 250 – ITS MAIN ADVANTAGES AT A GLANCE

- MAXIMUM SPEED AND EFFICIENCY

The new Performance Package ensures that the machining time is reduced and, therefore, guarantees a significant increase in efficiency for the machine. This is achieved through the seamless interaction between generator technology, process parameters, gap evaluation and drive technology in the QXD 250. - INCREASED SHARPNESS

Surfaces with a roughness to 0.1 μRa. This will sharpen your image – worldwide. - INCREASED FLEXIBILITY

For tools up to 320 mm in diameter and 250 mm in length. Virtually all requirements are met.

Your Contact

115 Enterprise Drive

Pittsburgh, PA 15275

USA

Phone: +1 412 2780655

Fax: +1 412 2780520

info-us@vollmer-group.com